Decorative thread wraps are a popular way to personalize a custom fishing rod, and many builders should really be called artists for their abilities. We see intricate designs ranging from simple trim bands to elaborate cross-wraps and even the use of non-traditional rod building materials to showcase craftsmanship and creativity. While they don't contribute to the structural integrity of the rod, decorative wraps are often used to highlight guide placements, transitions, or even display custom logos and patterns. For many anglers and builders, they offer a unique opportunity to create a one-of-a-kind rod that reflects individual style or brand identity.

Here comes the downside, or is it? Is it important to consider the added weight that decorative thread wraps can introduce to a rod, especially when performance is a top priority? Often multiple layers of thread, combined with the rod finish are used and we cannot deny they add weight, but how much and do we think there is an effect on the build?

What is too heavy?

I’m going to assume there is a line of diminishing returns based on how much decorative work goes into and then at some point the extra weight must have some effect. Just recently in the Mud Hole Live Rod Builders Workshop a post was made about marbling the entire rod all the way to the tip. I commented that although there was no law or rod building rule that says you cannot, it might have a negative impact certain rod blanks but not others. Possibly a very short offshore trolling rod would be a nice option for full marbling, but I would not recommend doing it to a 4wt fly rod.

So, before we get into what I found when wrapping, finishing and then weighing my sample the impact may be minimal in most cases but builders aiming for peak sensitivity and responsiveness should be strategic with their decorative work, balancing aesthetics with function. Hopefully, this will shed a little light and help builders continue to hone their craft.

Without getting too crazy, I wanted to create a decorative crosswrap that many builders can complete to give a baseline on what to expect from added to a rod build. I did take various weights of the blank, finish and at different stages throughout.

Parts List

Here is what I used.

Various ProWrap threads (Nylon, ColorFast, Metallic)

I did begin by weighing the bare blank before starting the wraps on the RBS Pro. As with any decorative cross wrap I use the CRB Butt Wrap Alignment Tool as it creates the perfect roadmap to follow once I start laying down threads. As you can see the blank weight is 1.544oz or 43.77 grams. Just for transparency sake these blanks listed on the Mud Hole Website are 1.53oz so we are a mere 14 thousandths off. Works for me.

Now that we have our starting weight, I got to wrapping. Honestly, I did not have much of a plan except to provide an open crosswrap with a mix of colors and materials. I did not weigh the separate braid from nylon or color fast but I might have to go down that road at some point.

Threadwork Finished

Just for scale I wanted to measure the wrap on this IS701ML and overall with the ends tied off, it is a little over 9 inches. With the thread work complete our new overall weight is 1.583oz or 44.88 grams that gives us an increase of .039oz or 1.11grams. Ok, so a mixture of thread and metallic braid doesn't weigh all that much.

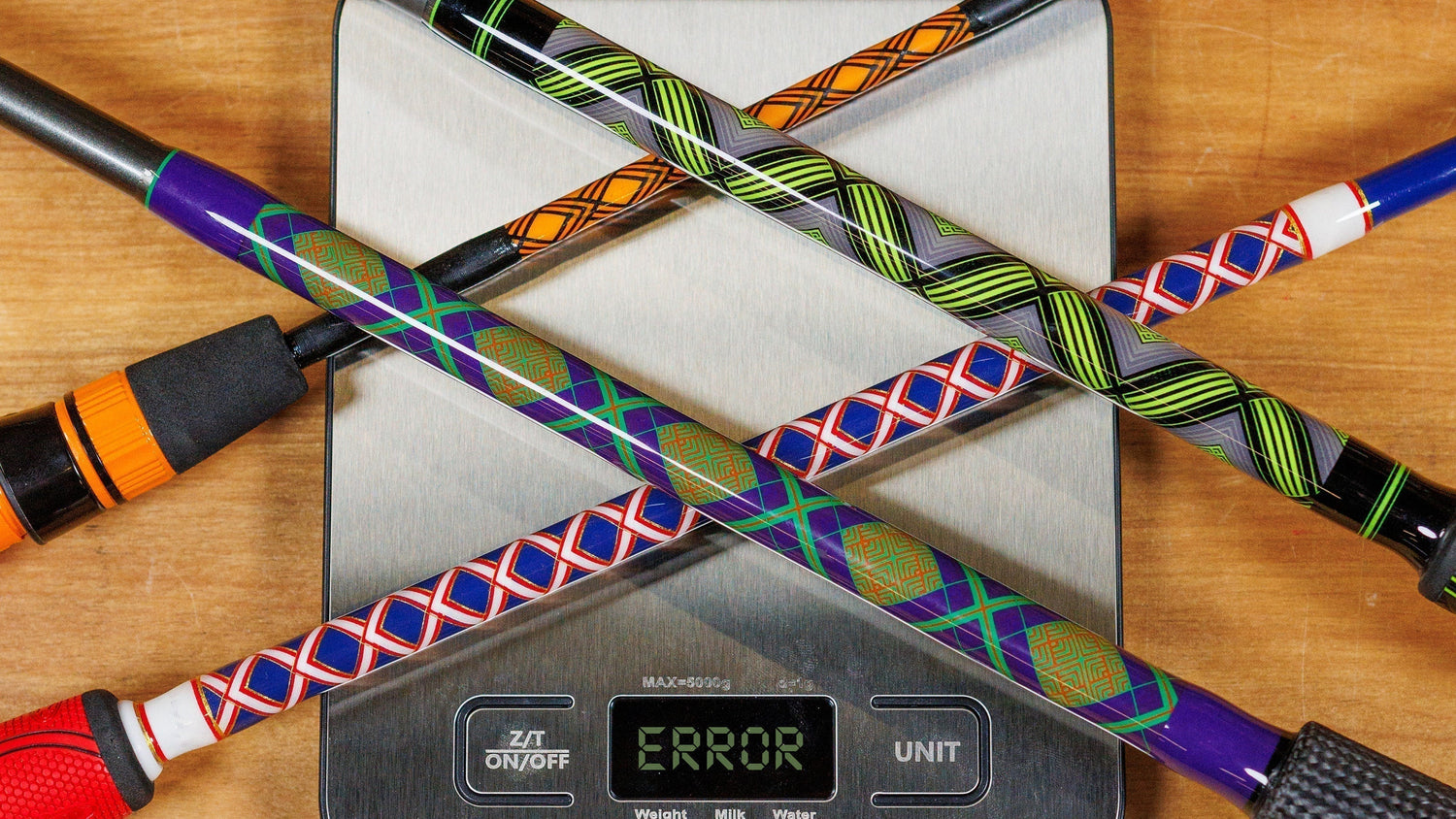

Here is an up close of the pattern.

I believe it was 68 thread passes with 4 braid passes just to give you an idea of the amount of thread. Many of the multiple threads were done in one pass which helps move it along faster. Whether you do one at a time or 2/3/4 threads at a time it all works. Check out one of our latest Mud Hole Live Episode #119 on this type of decorative work.

Is Rod Finish Heavy?

So it all comes down to the finish on whether or not a significant amount of weight is being added to a rod blank.

As I mentioned before I will be using ProKote rod finish and not the High Build version. I believe the best way to minimize the high and low spots that can occur when adding finish over cross wraps is to use multiple thin coats of finish.

To start I measure out 6ml of finish. That was 3ml of each the resin and hardner into the mixing cup. I did this by accidental habit forgetting I was only covering a short crosswrap and not an entire rod build. For the later coats I only mixed 3ml of finish. I did this over multiple applications and each time was very close in starting weight. Yes, I also weighed an empty mixing cup and then zero the scale. The mixing cups I have are .043oz but still zeroed my scale rather than doing additional math.

Coats of Finish

The first mix of finish was .224oz for 6ml of finish and after the first coat we measured .177oz of finish left for a total of .047oz used. Although I was not sure how much finish I would use I had a pretty good idea the first coat would use more finish than the following coats due to the absorption of the finish into the threads.

The second coat was .108oz of 3ml of finish and the remaining finish after the second coat was .066oz for a total of .042oz used. Not as far apart as I had thought it would be from the first coat to the second coat. I did take great care to add an appropriate amount of finish and caught any drips back into the cup.

Ok so after two coats we are looking good but I do believe we need a third or even fourth coat. As I was adding finish and measuring it dawned on me that doing a complete closed wrap might actually weigh less since you would most likely need less finish since all the thread stands the same height off the blank rather than adding multiple coats to smooth out the difference in thread high from the blank.

Two Coats Complete

So, we have two coats on and the first coat we used .047oz of finish and the second coat we used .042oz of finish. Time to find out if our measurements are correct and weight the rod blank.

I actually wasn't expecting it to be this close but starting with a 1.583oz blank with thread and then adding a coat of finish at .047oz and a second at .042oz the math says 1.672oz and the scale says 1.673oz.

Back to the bare blank of 1.544oz the thread and finish added .128oz which is a hair over 1/8th of an ounce for a crosswrap and two coats of thread finish. Not bad!

A Third Coat Of Finish

The third coat of finish measured out to .114oz and after the application it came out to be considerably less than the previous two coats, which I assumed as this progressed.

The Final Result

Looks like I used .029oz of finish for the third and final coat.

Drumroll....So the final weigh in we were at 1.7oz for a total of .158oz added over a completed cross wrap with three coats of finish!

Is that too much for certain rod builds? I do not think so, especially if it is added in the split grip area or just in front of the reel seat. I have exact builds of my Signature Series Technical Flats Rod and a couple have decorative wraps over the entire split grip while others do not and I can not tell a difference.

Why Can't I Feel the Difference?

Not to get too deep in the woods here but it is something to consider when choosing certain guides or whether or not to add a decorative wrap.

First, The Weber–Fechner Laws are two interconnected principles in the field of psychophysics: Weber's Law and Fechner's Law. Both explore how humans perceive changes in sensory stimuli, focusing on the relationship between a physical stimulus's actual change and how that change is perceived. These laws apply across all sensory modalities, including sight, sound, taste, touch, and smell.

As an example, after the thread wraps and two coats of finish we had added approx 1/8th of an oz. A measurement that is common in fishing. So imagine you have a 1/8th oz weight in one hand and I double the weight and place a 1/4oz weight in the other. I bet you would notice it instantly.

Now, if we take a fully built custom rod that weighs 3-1/8oz and then add another 1/8th of an ounce to make the rod 3-1/4oz, I can almost guarantee you will not feel it and for once, I have a little bit of science to back up my hair-brained ideas.

Hope this helps when decided on whether a decorative wrap is worth it on your next build. I say, go for it!