Learn 4 quick tricks for awesome guide wraps using nylon thread.

Easy Threadwork for Cool Custom Wraps

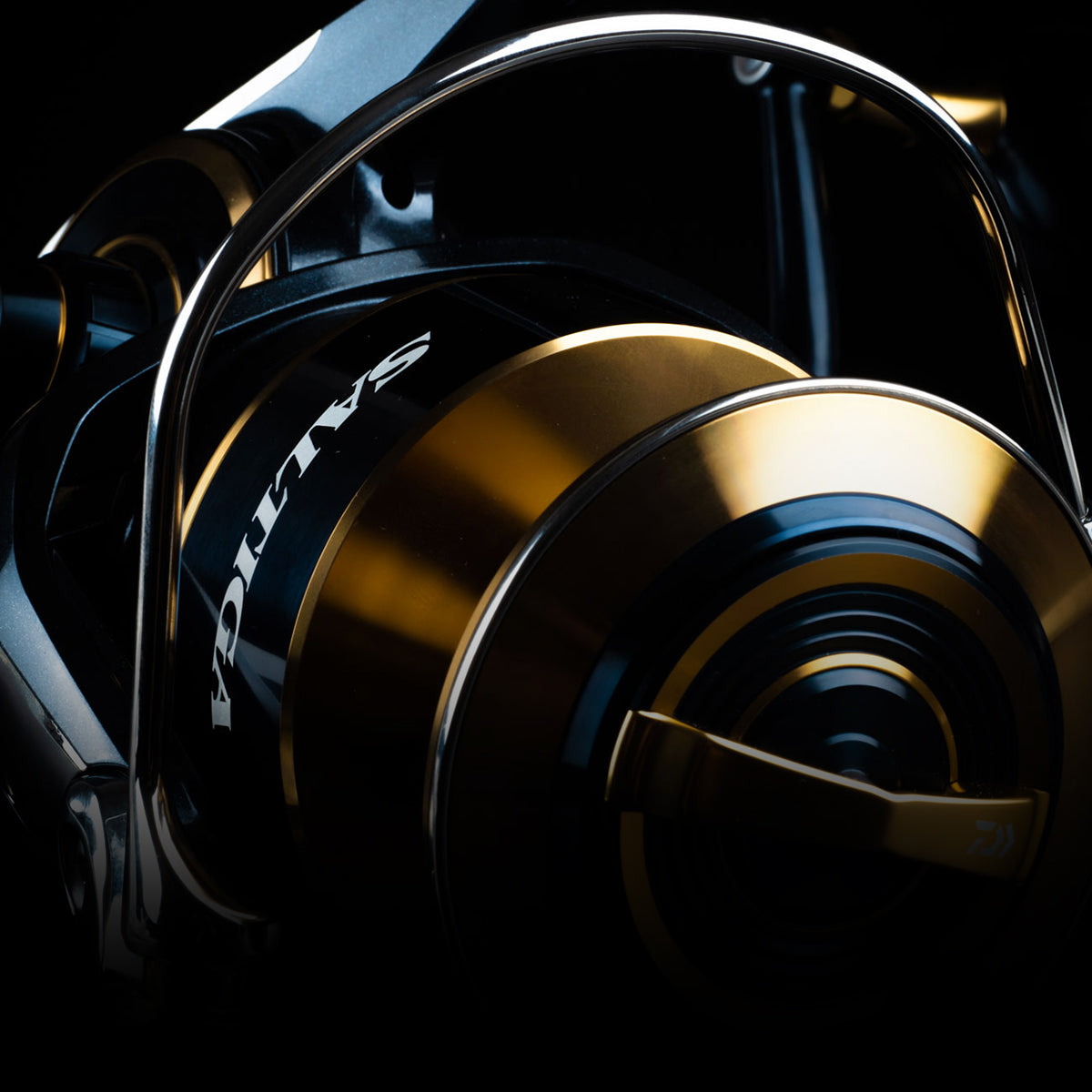

Part of rod building is developing new and exciting ways to make each custom fishing rod different from the last. While many of the components in rod building serve to dial-in performance, threadwork is where function meets true customization.

From the many thread colors to the imaginative wrapping techniques, custom threadwork gives rods a professional aesthetic to match its superior performance.

When it comes to taking Nylon Thread to the next level, use the following tricks for guide wraps that really wow on the water.

1. Remember the Blank’s Background

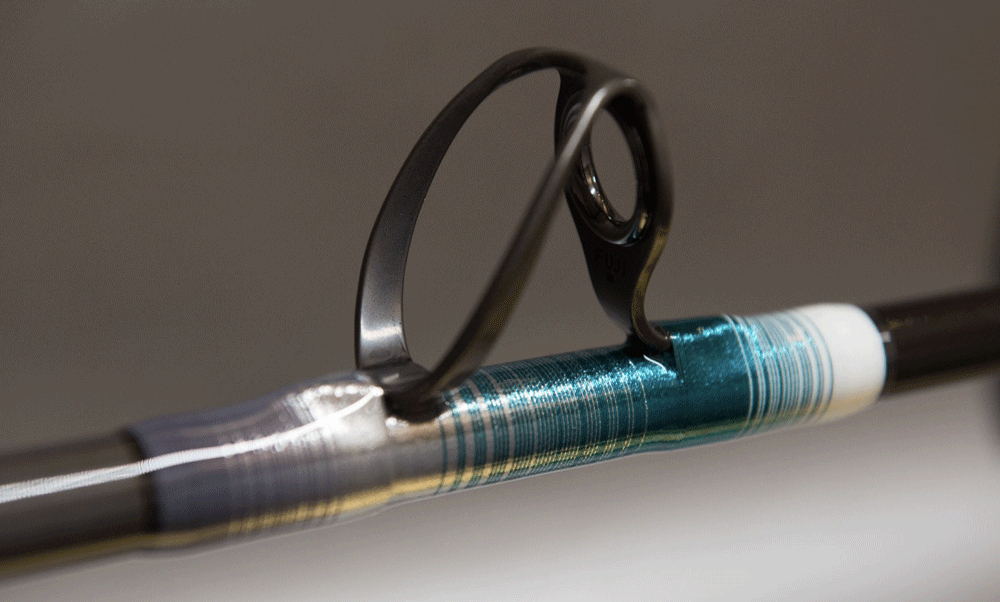

Before you pick out your nylon thread colors, pay attention to the color of your rod blank and how each thread will change color based on the blank’s background.

For instance, a red nylon thread looks very different on a white rod blanks as opposed to darker blanks like black, grey, or purple. The red will lighten up over the white blank, while turning more burgundy on the black blank and crimson over the purple.

As you can see, the unfinished nylon threads on the left appear different than the nylon wraps coated in epoxy on the right. While this is partially due to the epoxy, the difference between each truly comes from the each of the blanks' background colors.

So in order to get the appearance you desire on your finished guide wraps, consider how the nylon thread will look finished over your rod blank and then decide which color will provide your ideal results.

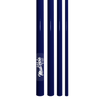

2. Blend Nylon Thread with Rod Blank

Since nylon thread has a tendency to darken with the application of epoxy finish, many rod builders find blending the guide wraps to the blank color creates a sleek final look.

Besides phoning into Mud Hole’s dedicated staff for advice, you can visually test the thread colors over your blank for a better look at the final color. Testing the thread prior to epoxying is the best way to be sure your thread color will truly disappear into the tone of the rod blank.

To test a nylon thread’s finished color, simply wrap a segment on the rod blank and brush the thread wrap with a light coat of water. The water will simulate the effect that epoxy has nylon thread and darken to show a preview of the final appearance.

Check out Mud Hole’s selection of premium Nylon Thread for Wrapping Rod Guides!

3. Pick a Thread Color that Pops

While some rod builders actively look for colors that will blend seamlessly with the rod blank, others prefer threads that contrast the rod blank. Choosing a thread color that contrasts the rod blank leads to guide wraps that will really pop on the finished rod.

For many rod builders and customers alike, a sharp custom fishing rod has a color scheme that is subtle yet eye-catching. The easiest way to meet this aesthetic balance is to complement the rod blank and the guide wraps with contrasting colors.

One key to remember is that lighter colors show up better on darker blanks while darker thread colors will stand out more on lighter or whiter colored blanks.

Start out with lighter variation of the color you want to end with and put a little water on the thread wrap to test the color's finished appearance. Start out with lighter variation, put a little water to test final color and do test wrap under where handle will be.

Sometimes lighting can also effect the appearance of the thread wraps, so it helps to expose the wraps to sunlight for a true color test.

Besides with over 80 colors of ProWrap Nylon Thread at Mud Hole, we guarantee you can find the perfect, eye-popping color for your guide wraps!

4. Add Color Preserver to Maintain Thread Tone

While understanding how a nylon thread's color will change after epoxy finish is important, it's also easy to apply color preserver to maintain the nylon's original aesthetic. For instance, ProSeal Color Preserver coats Nylon or Untreated thread so that the final threads maintain both their color and opacity.

During application, don't be alarmed by ProSeal's white appearance because it ultimately dries as a clear coat.

This special formula promotes thread penetration and can seal untreated threads in as little as one coat in preparation for epoxy finish.

Note: Really light colors may require multiple applications of ProSeal to stay true to the original color.

Catch all the Cool Nylon Colors at Mud Hole