Learn how using color pigments in epoxy became popular in rod building for decorations, repair work, and more!

Why Rod Builders Tint Epoxy Finish

Whether for decoration, repair, or just a touch up, color pigments bring serious benefits to custom rod building and this blog is here to explain why.

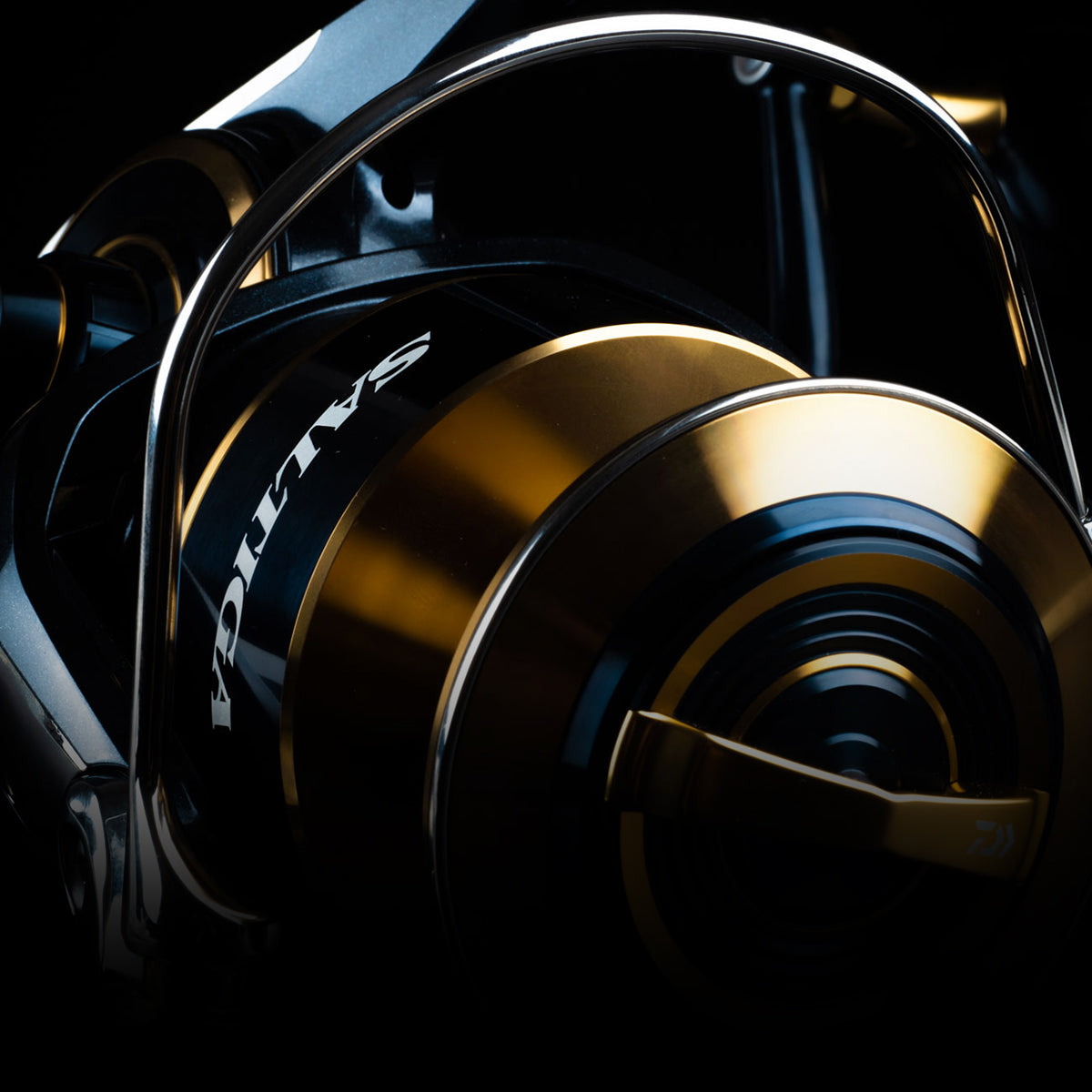

1. Fixing Loose Reel Seats

A loose reel seat is a real bummer on the water. Luckily, fixing it doesn’t take more than some epoxy glue, black pigment, and a drill.

Start with the reel removed, and carefully drill a hole in the top and bottom of the reel seat. Drill each hole in between your tape arbors, and make sure the top and bottom hole are on opposites sides of the reel seat.

Next, mix up your two-part epoxy glue. ProGlü works best because it is a flowing epoxy glue that will fill in any voids underneath the reel seat.

With the epoxy resin and hardener mixed together, begin adding some black pigment to the epoxy. Gradually add in small amounts and stir to get the color consistency to match the reel seat.

Then, draw out the epoxy with a syringe.

Inject the black glue into the top hole of the reel seat and keep pushing in epoxy until it leaks from the bottom hole.

Wipe off the excess epoxy with denatured alcohol and make sure the reel foot hoods are aligned appropriately.

Once the reel seat is in the right position, give it a full day to cure then you’re ready to go!

Click here for another way to Fix a Loose Reel Seat…

2. Making Epoxy Winding Checks

Some rod builders like to use color pigments in epoxy to create their own custom winding checks. While winding checks are readily available, finding the blank measurement to fit the winding check and ordering the component can take time.

Save time and make your own epoxy ramp, it’s simple!

First off, use an epoxy paste like ProPaste rather than finish because it’s the easiest to form into a ramp as you apply it. Stir the two-part epoxy glue together and then gradually add your powder pigment as you stir.

Gradually adding pigment and stirring the epoxy together helps get the perfect color consistency for the rod blank.

Next, mount your rod in a rod dryer and apply the glue as the rod rotates. Lay down more tinted epoxy glue where the ramp backs into the rod component and then less where the ramp will taper back down the blank.

As the epoxy begins to cure, you can form and shape the ramp even further with your fingers. Just keep the original epoxy mix close by and you can judge when it becomes workable without leaving any finger prints.

Note: Use some masking tape to protect reel seat threads.

Once you have the shape down, let it cure completely and you’ve successfully replicated the sleek, professional effect of a winding check on your custom rod.

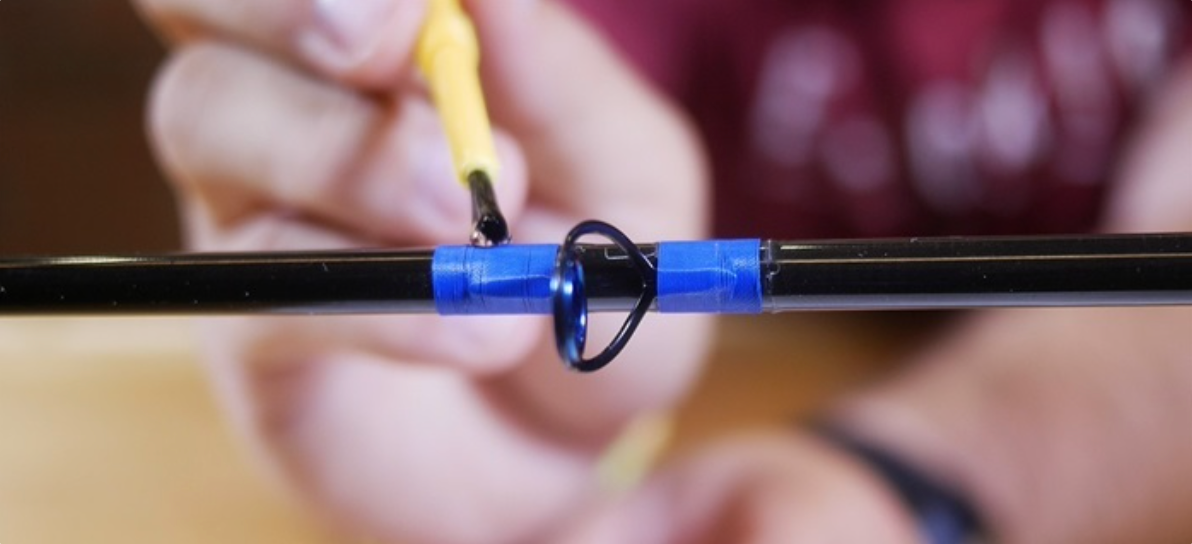

3. Coloring Finish on Guide Wraps

Another great way to use pigment in epoxy is tinting the finish over your guides. Whether it’s for added color, or to touch up a thread wrapping mistake, you can easily add pigment to your finish and over your guide wraps.

There are many options for pigments, including metallic options that add a shimmering style to your finished wraps.

Simply mix together a two-part epoxy finish, like ProKöte, and add in your desired pigment color.

For guide wraps with gaps or overlapping threads, use pigment to cleanly cover up the mistakes. Use black or darker tints for the best results when masking guide wraps.

Thread wraps are always tougher over light blanks like the one above. To trick the eye and maintain your rod’s appearance, begin adding tinted epoxy over the guide wrap.

After covering the thread wrap, let the epoxy cure and you will have a sharp finished guide wrap.

Whether tinting epoxy with color or adding metallic flake, it is a great option to dress up and touch up your guide wraps.

4. Custom Marbling with Pigments

Marbling epoxy as decoration took the rod building community by storm because it creates unique patterns that are practically impossible to duplicate. This means each custom marbled rod is not only unique to you, but a hot commodity for a rod building business.

From marbling butt wraps and guide wraps to everything in between, Mud Hole offers individual marbling products as well as two inclusive kits with all the essentials. Whether you need to stock up on marbling supplies, purchase a Starter Marbling Kit or even a Professional Marbling Kit, Mud Hole is the one stop shop that’s always here to help.

CRB’s marbling pigments are a non-toxic powder that can be used alone or mixed with other pigments for added effects. Another plus of powder pigments is that they don’t mix during the application, so that instead of a mush of color, you get a striking pattern or design.

To mix pigments, simply add color powders to separate epoxies before mixing them together to get the best results.

If there are other colors you want to add to your custom marbling, CRB Pearl Metallic Powder comes in 32 awesome pigments!