Rod ferrules are the connection points that join two or more sections of a fishing rod. They allow the rod to break down into shorter pieces for easier transport and storage, making multi-piece rods especially convenient for traveling anglers or those with limited space. While one-piece rods are still preferred by some anglers, modern ferrule designs have made believers out of many anglers that only fished one piece rods.

Ferrule Types

There are two main types of ferrules commonly used in fishing rods: spigot ferrules and tip-over-butt or sleeve ferrule. Spigot ferrules feature a smaller internal plug that fits inside the adjoining rod section, while overlapping ferrules involve one rod section sliding over the other. Both styles are designed to create a seamless, secure fit that maintains the rod’s integrity and performance. In higher-end rods, manufacturers often reinforce these connections using advanced materials such as carbon fiber or reinforced composites to prevent flex inconsistencies and ensure durability.

Is one ferrule type better than the other? Well, not necessarily, it has a little more to do with the materials used and the advancement in blank technology. Rewind back decades ago, sleeve-over ferrules posed a major challenge for rod builders. Not only was the blank material an issue but so was the mandrel design. To maintain strength, the upper section of the rod had to flare out significantly to fit over the lower section, creating a noticeable jump in diameter just above and below the ferrule. This disrupted the rod’s taper and often resulted in poor action and increased risk of breakage.

In contrast, internal ferrules—though more complex and time-consuming to produce—allowed the upper section to maintain a continuous diameter by fitting into the lower section rather than over it. This seamless transition resulted in more consistent tapers and smoother, more reliable rod action.

The Spigot Ferrule

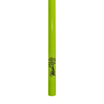

Shown above is a Steffen Brothers rod blank, which is an example of a spigot ferrule used in a fiberglass rod blank. The spigot ferrule is a type of internal rod connection where a smaller, solid piece—called the spigot—is permanently attached to one rod section and fits snugly into the hollow end of the adjoining section. This design allows the rod to maintain a more consistent diameter and taper across the joint, resulting in smoother flex and better performance. Spigot ferrules are used in all type of blanks from fiberglass to carbon and even modern manufactures still use them in certain models even if they also make tip-over ferrule multi-piece rods.

Shown above is a Steffen Brothers rod blank, which is an example of a spigot ferrule used in a fiberglass rod blank. The spigot ferrule is a type of internal rod connection where a smaller, solid piece—called the spigot—is permanently attached to one rod section and fits snugly into the hollow end of the adjoining section. This design allows the rod to maintain a more consistent diameter and taper across the joint, resulting in smoother flex and better performance. Spigot ferrules are used in all type of blanks from fiberglass to carbon and even modern manufactures still use them in certain models even if they also make tip-over ferrule multi-piece rods.

Above is an example of a modern manufacture building very high-end fly rods with spigot ferrules. This example if courtesy of Scott Fly Rods where not only is the blank carbon but so are the spigot ferrules.

A unique part of the spigot ferrule is the blank sections do not touch. The ferrule from the male side is a friction fit to the female side of the blank and you will always see a gap of 1/8" to 1/2" gap from coming completely together. Do not sand the ferrule or try to force the rod sections completely together, the small gap is by design.

Tip-Over Ferrule

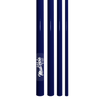

A tip-over ferrule is a type of rod connection where the thinner, upper section of the rod slides over the thicker, lower section. This design creates a strong and secure joint while maintaining a smooth exterior profile along the blank. Tip-over ferrules are more common in today's multi-piece rod whether they are fly, conventional or spinning rods. From the Mud Hole Color Series Fly and two-piece conventional as well as the MHX Fly, conventional and travel blanks are all tip-over ferrules.

Thanks to advances in high-tech graphite, stronger scrim materials, and modern rod design, today’s tip-over ferrules are slimmer, more efficient, and much smoother than their predecessors. Ultimately, choosing between ferrule types comes down to personal preference: some anglers favor the sleek, streamlined profile of internal ferrules, while others appreciate the ease of use and low-maintenance nature of tip-over designs.

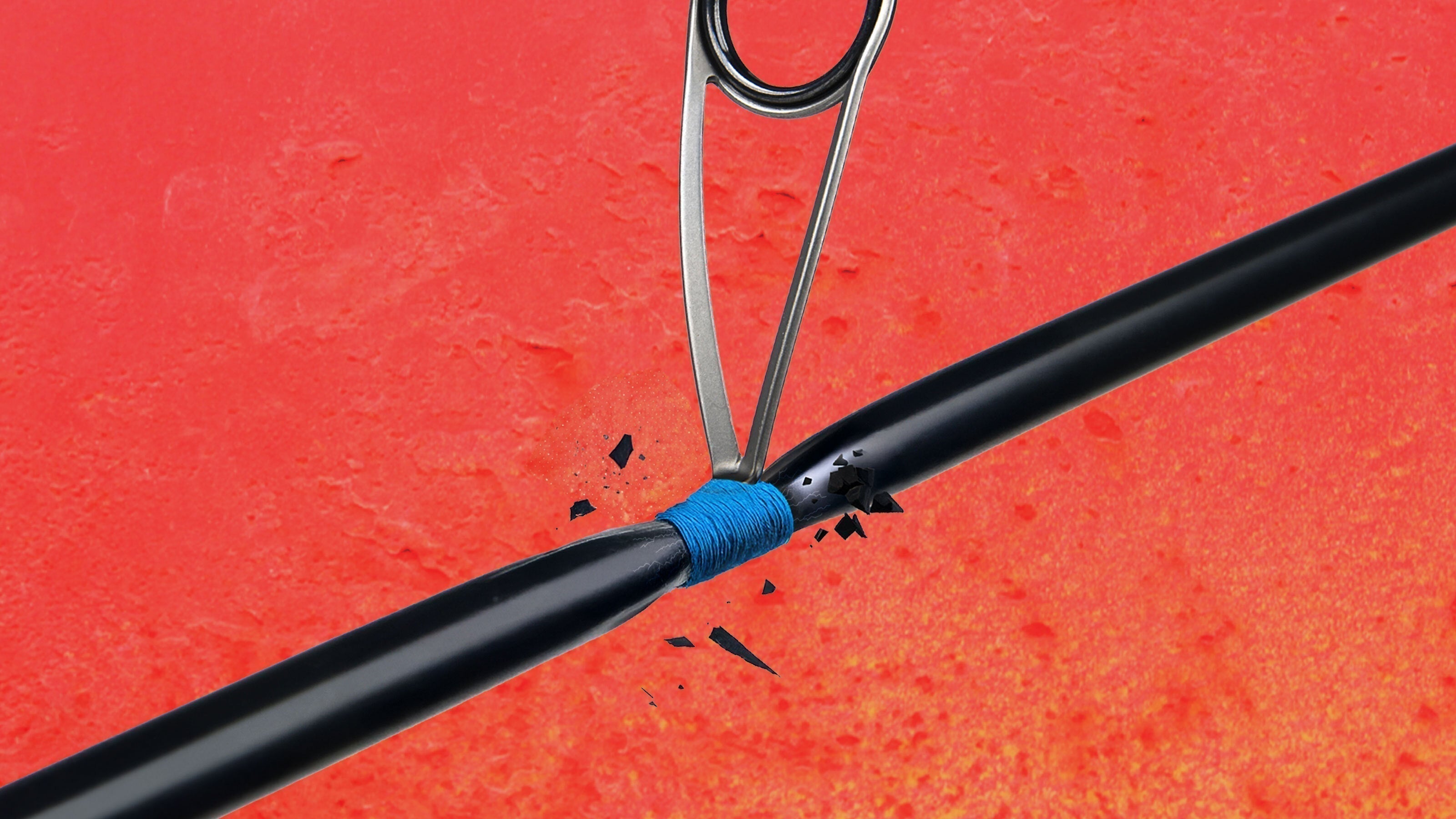

Should You Wrap Ferrules?

I always wrap the female side of the ferrule and reccommend builders do as well. Although modern ferrules are reinforced during blank construction, a simple threadwrap and finish can provide added insurance against ferrule damage. Ferrule wraps reinforce the joint between rod sections, helping to prevent cracking, splitting, or loosening over time. The thread wrap, sealed with finish, distributes stress evenly around the ferrule, reducing the risk of failure at one of the rod’s most vulnerable points.

Beyond structural integrity, a well-executed ferrule wrap can also enhance the rod’s appearance, allowing for decorative thread work that matches the rest of the build. Although the common belief if to wrap the ferrule twice the length of the diameter of the rod blank, I tend to air on the side of what is more visual appealing. Typically, I wrap all ferrules the same length or very slightly shorter as you progress out towards the tip. Whether for added strength, longevity, or style, wrapping ferrules is a small step that makes a big difference in a custom rod’s quality and reliability.

Metal Ferrules

What happens when you are building a bamboo rod or accidentally create a multi-piece rod from a one-piece? Well, the metal ferrule in most cases is your only option. Granted, there are bamboo fly rods made today that cost several thousand of dollars and use nickle-silver ferrules. It is part necessity and part tradition. Don't worry, you can also use brass ferrules for your rod building projects. They are not as expensive as the nickle-silver and as well as lighter weight, but the tolerances are perfect.

What happens when you are building a bamboo rod or accidentally create a multi-piece rod from a one-piece? Well, the metal ferrule in most cases is your only option. Granted, there are bamboo fly rods made today that cost several thousand of dollars and use nickle-silver ferrules. It is part necessity and part tradition. Don't worry, you can also use brass ferrules for your rod building projects. They are not as expensive as the nickle-silver and as well as lighter weight, but the tolerances are perfect.

For the repair aspect of ferrules, they can be very useful in many different situations. In my opinion you can also utilize ferrules for long rods to create a more travel friendly option. A word of caution though, if you are going to use a metal ferrule and have a choice where to put it, I would try to place it as close to the butt section as possible. For example, if you need a 9 foot rod for jetty or surf fishing but need it to be shorter, try an 80/20 split. That will take off almost 2 feet of the butt section but leave over seven feet of the top section intact. It can create enough packability to carry it easier in your vehicle or even store at home but once together it will feel much more like a one-piece than if you did a 50/50 split.

In addition to ferrule placement, I prefer to use ProGlu for attaching ferrules as well as doing repairs that occur out into the blank itself. Reason being, unlike many 2 part epoxies, ProGlu is specifically formulated to remain flexible after it is cured. For situations when you need to sleeve a rod blank, make a repair or add a ferrule, I always choose ProGlu.

One final thought regarding ferrules, if your guide spacing has a guide falling at or very close to the ferrule, you can just incorporate that guide into the ferrule wrap. Most builders, including myself will adjust the spacing so that if a guide is within 1/4-1/2" of being on the ferrule, I will be sure to adjust the spacing so that guide lands inside the ferrule wrap rather than creating a shorter ferrule wrap then a separate guide wrap.