When building a custom fishing rod, one of the most critical yet often overlooked factors is maintaining proper thread tension while wrapping guides. It may seem like a minor detail, but the tension applied to the wrapping thread plays a major role in both the structural integrity and appearance of the finished rod. Getting it right ensures your wraps are secure, your guides stay in place, and your final product performs reliably on the water.

Not only can thread tension be related to performance, it also necessary to achieve a clean, professional appearance. Even, tight wraps produce a smooth surface, allowing epoxy finish to flow evenly over the threads. This prevents blotches, gaps, or ridges in the finish that can affect both aesthetics and performance. Consistent wraps are also easier to burnish, improving the overall look of the rod and ensuring the thread lies flat and secure.

How To Get Proper Tension

So, although I do not have an exact way to achieve the proper thread tension on all wrappers, I can provide some tips for those using many of the CRB Wrappers that feature a tension rod. In addition, there are things to look for to determine if your wraps are too loose, too tight, or just right.

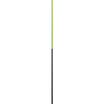

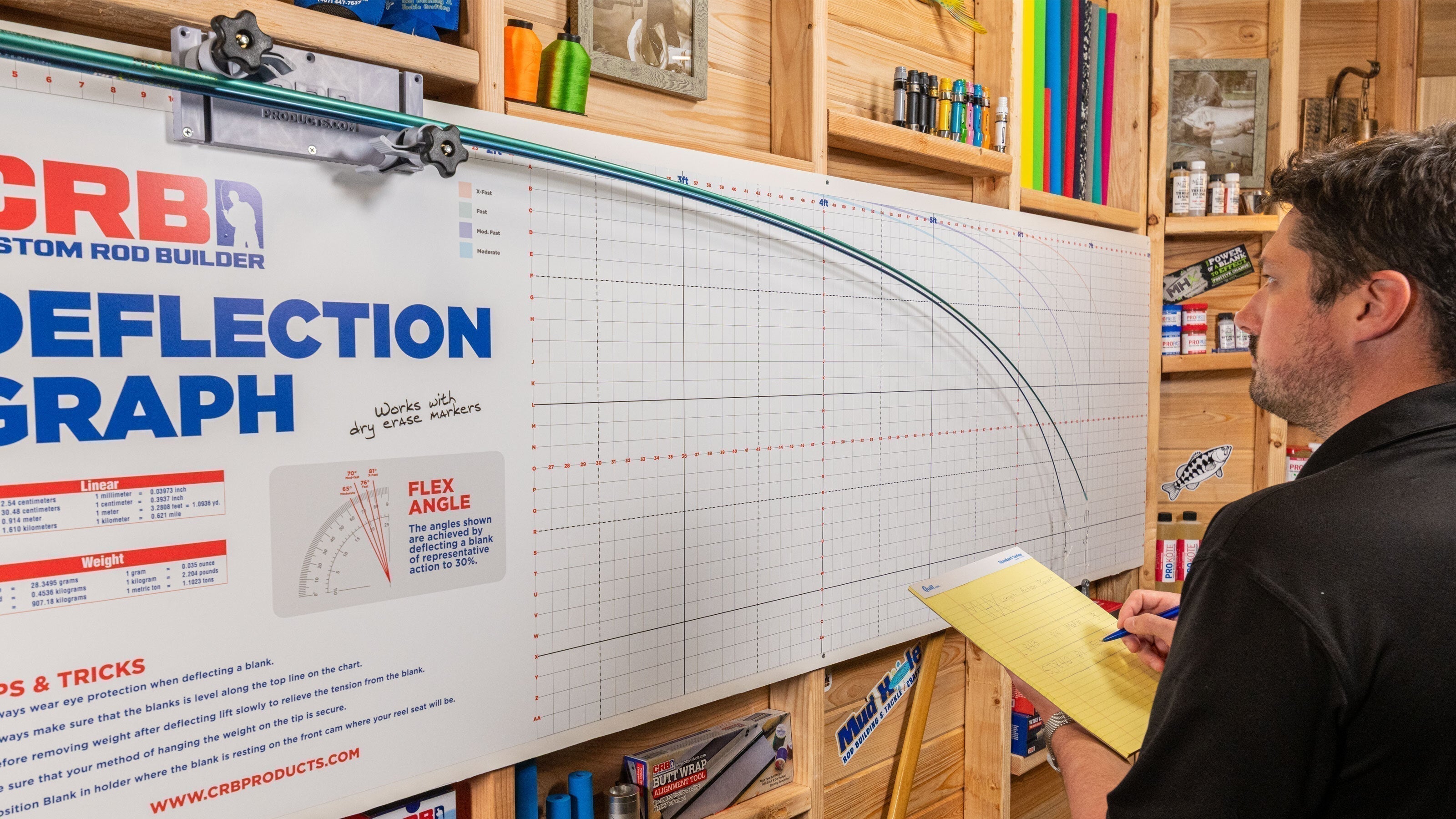

This photo above you will see the proper setting of thread tension when using a CRB wrapper. You have heard us in the past refer to the 90 degree angle method and this works for any size thread whether you are on a hand wrapper or power wrapper with a tension rod.

If you are using a wrapper without a tension rod a little trial and error might be needed to settle on the right tension for your specific wrapper. One of the signs you do not have enough tension is trouble starting your wrap. If your first couple wraps spin on the rod blank there is not enough tension on the thread to lock it down. Alternatively, if you find your thread not wanting to climb the guide foot, you might have too much tension, as long as you have a nicely prepped guide foot.

As you complete your wrap and tie it off, your final test of proper tension is the ability to move the guide foot to finalize the alignment. You should not be able to effortlessly move your guide foot around once it is wrapped but with a little effort you should be able to make minor tweaks to align into position.

Too Much Tension

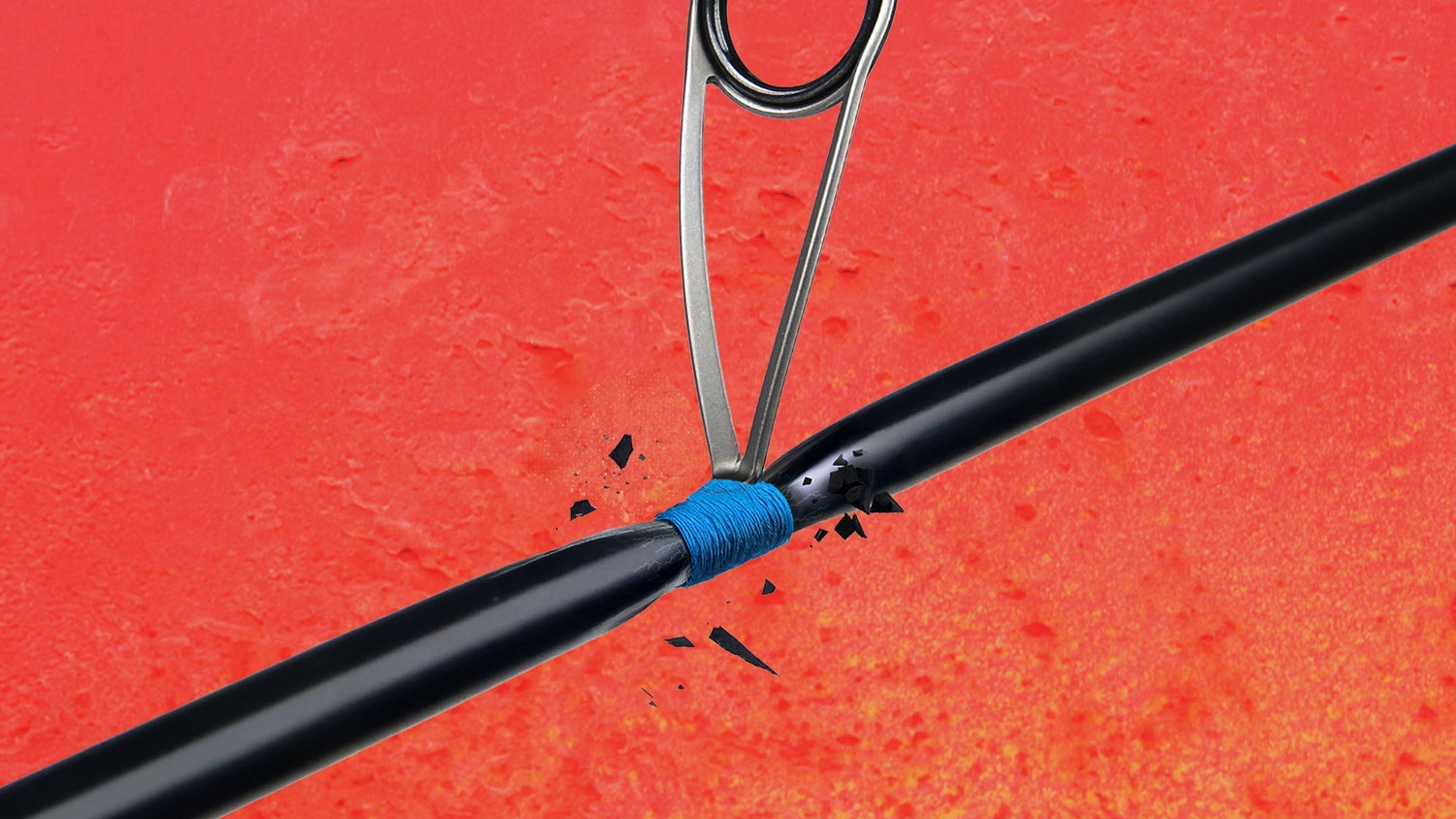

So if the 90 degree angle is perfect, here is what it looks like when you are wrapping too tightly. When we get calls that your tension rod breaks, we understand it might be frustrating but it might just keep you from breaking your rod blank.

If your tension rod is flexed over like the image above or even further, you need to back off the tension. It does not matter if you are building an offshore rod to catch blue marlin, it doesn't need to be that tight.

You might think, how can wrapping using thread that breaks between 2 and 5 pounds cause damage to a rod blank? Well, as you wrap a guide onto the blank the tightly stacked wraps can create an issue when the rod blank flexes. As much as we do not want our guide to move, the rod blank is designed to flex but the differences between stainless steel and carbon can be huge when force is applied. With some very delicate and then walled blanks, the wrapping force can actually deform the blank against the guide foot.

As you can see, even with using size B nylon thread, excessive tension when wrapping can force that guide foot to create a flat spot. If the blank is deformed enough it can cause a fracture. Or, think of it like you are flexing a rod blank over your knee or against the gunwale of a boat, causing a break.

As you continue to grow in rod building you will get accustomed to the proper tension, even without the tension rod. In my opinion, if I had to choose between wraps that are too loose over wraps that are too tight, I would choose the looser of the two. Now, that's not to make you nervous or overthink your wraps, but a major downside of tight wraps is rod damage. Loose wraps might be a little unsightly or frustrating but will not cause damage.

The Frustrations of Loose Wraps

Thankfully, the majority of loose wraps are mostly just unsightly. But, one thing I believe most rod builders experience when learning is the unraveling wrap. We have all been there, and it typically happens as the worst time, when applying finish. As luck would have it, the loose wrap isn't locked down and then as you press the finish brush against the wrap it is turning in the opposite direction of the wrap and like magic... it unravels.

Another hallmark of a wrap that is too loose is the blank color showing through. Granted, you can make an ugly wrap that is not properly burnished with the right tension but having a loose wrap is not easy to stack or burnish. You will be left with a wrap that has wavy lines because of the over burnishing and will end up being more work than just setting the proper tension.

The Perfect Wrap

Now, before you start pointing fingers or picking apart my wraps, I'm just here to break down the perfect wrap and not claim that mine are flawless. In reality, I believe a wrap can be perfect without being flawless. A guide wrap with the proper tension that is tightly packed and burnished with straight lines and no gaps is perfect, but will always have flaws under a close eye. That is what makes custom rod building so great. We all should strive for perfection but also realize, as rod builders, we create things by hand so there are always going to be flaws.

This blog was not intended to give you something else to worry about in regards to thread tension, but if you are having a few hiccups with your guide wraps, hopefully something as easy as adjusting the tension can help.