When building a custom fishing rod, prepping the guide feet before wrapping can be a polarizing topic among builders. Some find it to be a crucial but often overlooked step that can significantly impact the quality, durability, and appearance of your finished rod. While others call it a waste of time, compromising the corrosion resistant coating on a guide.

So, who’s right? Well, I have personally seen both viewpoints to have merit.

Whether you’re a beginner or an experienced builder, taking the time to properly prepare your guide feet can certainly save some frustration down the line and help to promote tight wraps.

For those in support of prepping your guide feet there are several positives.

Checking Your Guides

First and foremost, whether you grind the feet or not, guide prep can simply be looking over your guide for any imperfections. Even the best guides have a rare burr on the foot or a chip in the ring. Things can happen and it is always good to find those imperfections before wrapping, finishing, or worse, when fishing. Damaged or frayed fishing line, lost fish or even a broken blank can all be avoided by taking a few minutes to look over your guides.

Smooth Thread Transition

One of the main reasons to prep a guide foot is to create a smooth transition for your wrapping thread. We’ve all been there, you lay down a few wraps on the blank and once you reach the guide foot it is like you are trying to jump and touch the basketball rim but can’t jump. If the guide foot is too blunt or squared off, the thread can bunch up, slide off, or create an uneven thread line that just creates more work to get it to look right. A well-tapered foot allows the thread to climb naturally onto the guide, resulting in a tight, clean wrap with minimal effort.

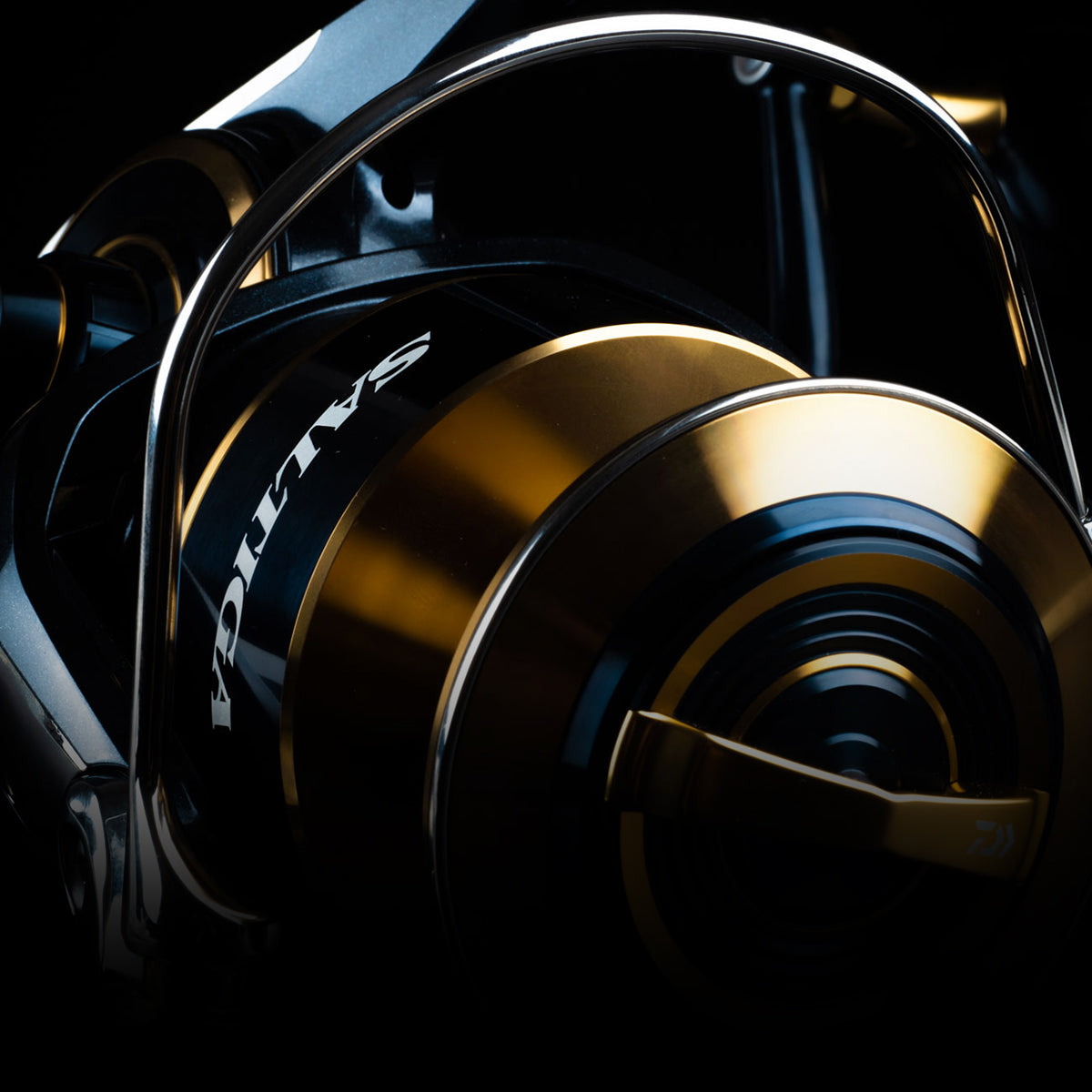

Notice the nice tapered foot on the left that comes to a point whereas the foot on the right is a very blunt nose and would require the thread to jump up onto the foot.

Along with the smooth transition, it creates clean lines and a more professional look. I think we have all walked the isles of a big box store's fishing rod section and looked at the build quality. It can be quite weak, to put it nicely. As you look over the components, guide wraps, and finish work, it can make you wonder...if they were careless while building the rod, what else did they skimp on?

As custom rod builders, we are happy to go the extra mile to build a better rod. We take the time to choose the right components, properly set up the handle section to our preferences and arrange the guides along the blank for optimal performance. So, what is an extra 3 minutes to make sure the guides are prepped?

Finally, you will find the better the transition, the less air will be held under the thread along the guide foot. Trust me, that can save you the frustration of the dreaded air bubble that is visible under a beautiful, translucent nylon wrap. It makes me mad just writing about it.

In the photo above you can see the bunching of the thread on the front of the foot that is barely showing through the finish. In addition to the thread bunching, you can also see the air bubble trapped in the finish that is under the thread and alongside the guide foot. Those are two examples of what can happen when the foot needs a little prep.

Proper Steps to Prep

1. Inspect the Foot:

Start by closely inspecting the guide foot under good lighting. Look for any visible burrs, sharp edges, or inconsistencies in the shape. Run your finger or a cotton swab along the edge to feel for snags. While you are checking the guide, be sure to inspect the ring as well.

2. Taper the Front Edge:

Use the CRB Guide File, rotary tool, or fine-grit sandpaper to gradually taper the front edge of the guide foot. You want a gentle slope that allows the thread to transition smoothly. Avoid removing too much material—just enough to round off the edge.

3. Smooth the Underside:

It’s important that the bottom of the guide foot, where it contacts the blank, is also smooth. Any imperfections here can scratch the blank or prevent the guide from sitting flush. There are times when grinding the top of the foot can roll the edge and create a burr on the underside. We want to avoid that. Lightly sand or file the underside to ensure even contact with the rod.

4. Polish the Edges:

This is one step you might be able to avoid unless you are grinding the foot on larger guides where you need to remove more material. After you have created the proper slope, go over the edges with very fine sandpaper (e.g., 400–600 grit) or a polishing pad to remove any micro-burrs or roughness. This final step ensures the guide foot is safe for the blank and easy to wrap over.

5. Clean Before Wrapping:

Before wrapping, wipe the guide foot with a clean cloth or alcohol pad to remove dust and metal shavings. This ensures a clean surface for your thread and epoxy. I believe this is an often-overlooked step that can also create what appears to be the guide foot rusting.

Guide Prep Negatives?

So, can guide prep go wrong? Are you risking stripping any corrosion resistant coating from your guide foot? Well, there are many rod builders that believe not only guide prep is unnecessary but can also create issues with your rod builds.

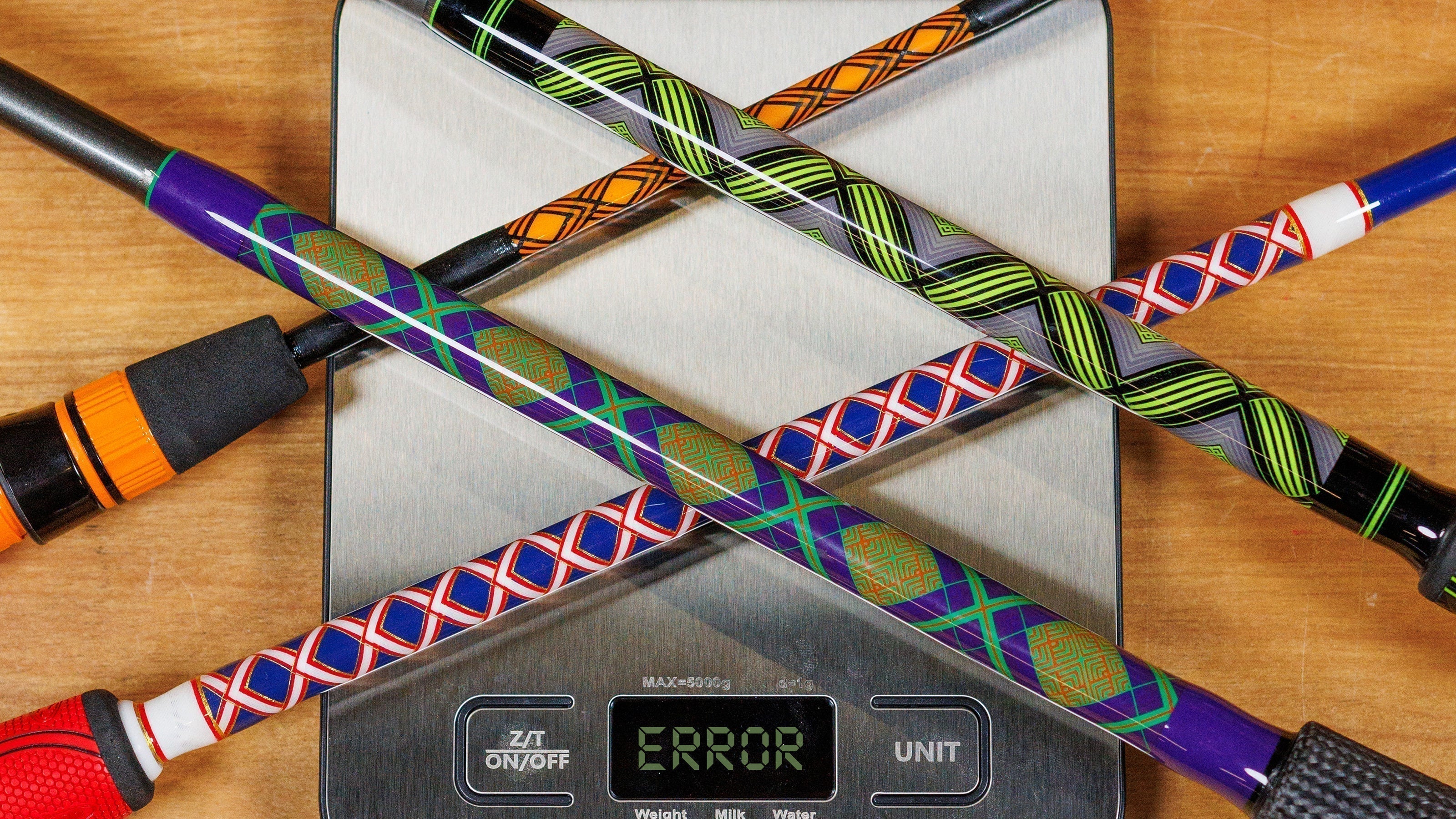

In my personal opinion the jury is still out. I do tend to grind my guide feet but have not always had a rust issue. I have also tested using less rod finish as well as not running the finish out on to the blank. I wanted to see if I would get water intrusion with less finish and less of a "seal" around the thread on the rod blank.

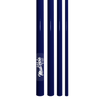

Well, I do have some photos of a build that has seen years of service on the saltwater flats with my clients and it is pretty obvious I am getting some sort of rust or staining down on the tip of the guide foot.

As you can see, there is staining and this was on one of the builds where I used very little rod finish. Although the guide is still very much locked tightly on the rod blank, you can see there is zero finish around the top of the threads. The gaps around the foot and under the thread is very much filled with finish but there is not any finish out on the rod blank at the top.

I do have another rod build that is much more recent but the foot has been filed but I did add more finish as well as I made sure to clean the foot after I filed it down.

Without cleaning the guide foot after filing or grinding, you can actually contaminate the stainless steel on the guide foot with particles from the file. These steel or iron particles can compromise the stainless-steel’s protective oxide layer, leading to rust and loss of corrosion resistance. So, not only can the plain steel or iron particles rust but you also get a reaction due to dissimilar metals.

So, I am not saying you will be ruining your guide by grinding the feet but I wanted to be sure you are aware there can be things to look out for.

We know that saltwater environments can wreak havoc on your components, which is why I take time to test things like you see above as well as recommend buying well known and trusted components when venturing into the salt.

Prepping Black Frame Guides

Not to throw another wrench into your guide prep but I get the question about prepping black frame guide feet and then wrapping with nylon thread. You will most likely see where you sanded off the black coating from the frame. Some people do not have an issue with that and others do. What is the fix?

Is it as easy as just using a sharpie? Well, kind of but I do not particularly like to do it. The reason is that Sharpie Permanent Markers can harm stainless steel and even titanium due to the presence of chlorides and other halogens in the ink. Do I believe that a Sharpie will cause significant corrosion to the bare metal when coupled with saltwater exposure? I doubt it but I wanted you to be aware.

Still want to use a Sharpie? Well, they do make what they call a T.E.C Sharpie which is a special high purity Sharpie "Trace Element Certified" (T.E.C.) markers meet the requirements regarding trace element content for the nuclear energy, aerospace, electronic, aeronautic, and ship building industries. Yes, they are more expensive at about $10.00 per marker instead of $3 for a regular Sharpie.

You can also choose a paint marker or even a quick spritz of RUST-OLEUM spray paint in black to cover the unsightly bright metal showing from guide prep. This is an unnecessary step when using Color Fast Threads as you will not see through them as you will with Nylon Thread.

So, should you always prep your guide feet? I rarely say ALWAYS, and this is one of those cases why. There is a lot that goes into what components, where you fish, what rod you are building, and even your skill level that can go into making that final decision to prep your guide feet. Hopefully I have shed a little light on to the pros and cons of guide prep and provided information to help you as a rod builder make the best decision for your next custom build.