Find out how to remove and repair damaged portions of your push pole, so that you can return to the platform with a push pole performance you trust.

Fixing Damaged Push Poles with Replacement Parts

Regardless of the push pole material or brand, accidents happen. Sometimes it’s due to rough conditions or even user error, but honestly, it can happen in a gas station parking lot just as easily.

Whether cracked and leaking, or completely broken and severed, push poles take on a lot of the dirty work and naturally, this can lead to damage.

So the bad news might be a broken push pole, but the good news is, you can save what’s left and use the following instructions to completely rebuild your push pole!

**Don't miss the video tutorial at the bottom!**

3 Steps to Remove Broken Push Pole Pieces

Before repairing the push pole, you have to assess the damage and remove what’s broken in order to salvage the remaining components.

From a cracked section, to a damaged fork or point, start by identifying what exactly needs to be fixed and replaced. Then, you can order the appropriate replacement parts, or even contact a customer service rep for assistance getting exactly what you need.

After you’ve done the preparation for replacement parts, you can move on to removing the broken components of the push pole.

1. Use Heat Gun to Undo Epoxy Bond

If you’re replacing a section or fork and tip, the first step is to undo the epoxy bond attaching that particular component to the push pole.

For instance, to replace a fork—you must first remove it and this process starts with a Heat Gun.

TIP: For loosening epoxy, adhering rod skinz, and more, a heat gun is an awesome tool in custom rod building.

Start by turning the heat gun on it’s lowest or lower settings, this is important because although you do want to undo the epoxy securing the piece in place, you do not want to harm the epoxy within the push pole that holds the fibers together.

With the heat gun on the low setting, wave it up and down about an inch above the damaged area, while also rotating the push pole to loosen up the adhesive bond.

Keep in mind, the tip and fork as well as the ferrule are installed roughly 3-4 inches inside the push pole. So as you wave the heat gun up and down the push pole, make sure you are heating the interior section holding onto the push pole.

Continue heating the section for a 4-5 minutes and check periodically for any movement or sign that the epoxy is loosening up.

2. Twist Fork/Point From Push Pole

As you begin to feel the epoxy loosen up, you can move on to actually removing the component from the push pole.

It’s best to use an extra set of hands from your rod building buddy to successfully remove the damaged component.

TIP: Avoid touching the area where the heat gun was applied, this area will remain warm even after the heat gun is removed.

Using an extra pair of hands, firmly grab the component you are removing (fork, tip, or pole section) and twist it, while your help does the same—except twisting in the opposite direction to completely severe the epoxy bond.

TIP: It shouldn’t take too much force to do this, so apply more heat as needed if the bond is still too firm to severe.

3. Clean Up Push Pole Components to Reuse

If it’s the pole section that is damaged, you can often salvage and reuse the fork or point pieces, and vice versa for the pole if the end components are damaged.

TIP: If the pole section is damaged, make sure you cut and remove all of the damaged fibers before re-ferruling and installing a new replacement section.

To clean off dried epoxy resin from within your push pole and off of your push pole components, use denatured alcohol and some medium (80-grit) sand paper to remove the old epoxy.

TIP: Before installing replacement parts, sand the inside of the push pole so that the epoxy adhesive bonds better within the push pole.

See How Rod Builders Repair Broken Push Poles:

Watch as Mud Hole Live’s Chris Adams walks you through the steps to remove old, damaged push pole parts, and then, salvage the quality components you have left for repairs.

Order Push Pole Replacement Parts & Repair Kits

Sure, you can buy a replacement MHX Push Pole Section, but you can also find Push Pole Replacement Parts at Mud Hole.

Like rod repair, fixing a push pole is a great way to save the performance of your equipment as well as some money along the way.

Browse the supplies below to get you and your push pole back on the platform:

Push Pole Replacement Parts

First off, identify what components need fixing and order the appropriate replacement parts for the repair.

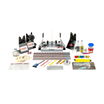

We also offer Push Pole Repair Kits that include everything you need!

The Glue Kit for MHX Push Pole includes everything from epoxy and mixing supplies, to a replacement ferrule and some safety gloves.

These repair kits are awesome because they help fix your push pole in just one quick order!