Rod building thread has always been something that comes up with new rod builders, and right fully so. They might have a storage bin of colorful thread from a past or current family members sewing collection or they are just in a bind for a DIY guide repair, so what's the harm?

Well, I am not necessarily here to tell you that you can only use thread that is labeled for rod building but I am here to give you so advice and things to look for before you make a mistake and create double the work for yourself. Trust me, thread that is approved for wrapping rods is not just something made up in marketing departments to sell more components.

Rod Wrapping Thread

Rod building thread is specifically engineered to meet the demands of securing guides and finishing a fishing rod, which sets it apart from regular sewing thread or fishing line. Made from high-quality nylon or polyester, it offers just the right amount of stretch to lock guides firmly in place without slipping, while maintaining the strength needed to withstand the stress of casting and fighting fish.

Unlike many common threads, rod building thread is free from waxes, oils, or coatings that can interfere with epoxy penetration and adhesion, ensuring a smooth, durable finish. It also comes in a wide range of sizes and colors, allowing builders not only to achieve functionality but also to add custom design and style to their rods. This balance of strength, stretch, finish compatibility, and aesthetic flexibility is what makes rod building thread an essential component in custom rod construction.

Manufactures like Pro Products and Fuji lead the way with nylon and polyester threads specifically designed for rod building. In addition, they have unique offerings like Metallic, Metallic Braid, and multicolors threads to give rod builders an almost infinite array of options to create a fishable work of art.

Manufactures like Pro Products and Fuji lead the way with nylon and polyester threads specifically designed for rod building. In addition, they have unique offerings like Metallic, Metallic Braid, and multicolors threads to give rod builders an almost infinite array of options to create a fishable work of art.

What Can Go Wrong?

For those that follow along with our blog as well as Mud Hole Live episodes, you know I love to show the "what not to do" just as much as the correct way. We all make mistakes in rod building, some can be avoided by just practice and honing your craft while other mistakes can be avoided by using the right product for the job.

Let's start with the number one question regarding thread. Can I just use sewing thread? Well, not really. I am not giving you a hard no because there are threads that you can use, like Madiera, but certain precautions need to be followed. Madeira Polyneon thread is a high-quality polyester thread known for its vibrant colors, strength, and resistance to fading, making it a popular choice for decorative wraps in rod building. Its smooth finish and durability allow it to lay flat and accept epoxy well, giving custom rods both performance and a polished, professional look. Here is my warning... You are more than likely going to need to coat the Madiera thread with color preserver before adding finish. Also, when I say "more than likely", I mean you should, to be safe.

I have been very open about my lack of color preserver use but in the case of using a sewing thread it is acceptable and in my mind, mandatory. Here is warning number two. Not all sewing or embroidery threads are created equal. The Madiera is smooth, vibrant and handles like standard rod wrapping thread. Below is an example of which sewing thread not to use.

This is polyester "sew all" thread that you find at most crafting or sewing shops. Notice the fuzziness of the thread. Not only does this thread not absorb the finish well, but those hairs create a nightmare. But, can't you just add finish and trim the fuzz or add multiple coats. First, you are creating way more work for yourself and two, here is what it looks like even with a health amount of finish over the thread.

If that is something you want to deal with just so you don't have to buy a rod building thread, have at it. I think we can agree to just call this the caterpillar effect.

The Fisheye Effect

Another issue that can arise with the incorrect thread is what we call fisheye. If you have spent time researching rod building from youtube videos to information on the Mud Hole Live's Rod Building Workshop facebook group, you have probably seen the term fisheye. It occurs when the thread or any type of base you are apply rod finish over reacts with the rod finish and actually repels it.

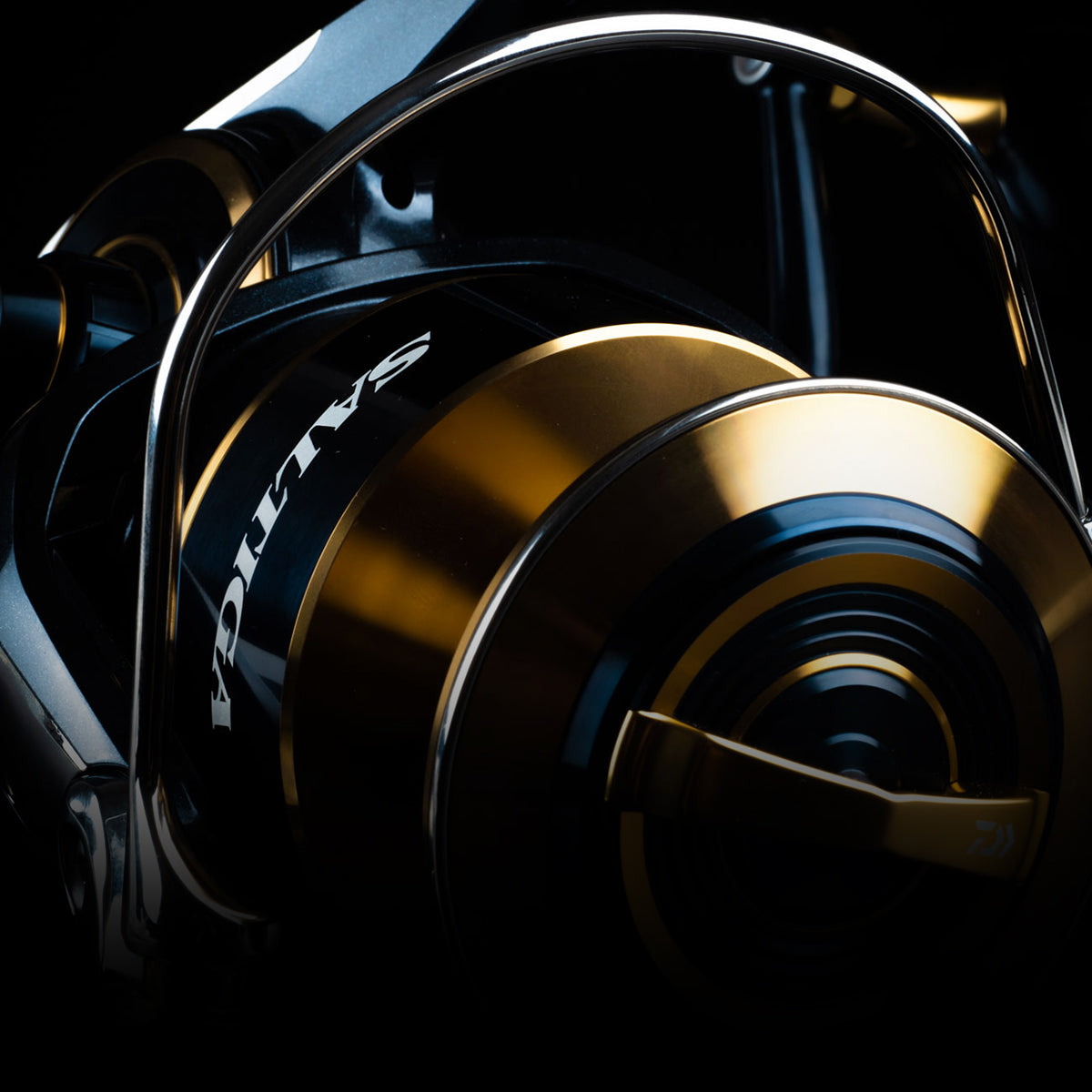

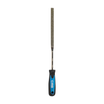

This can happen with thread that is not approved for rod building or due to a contaminate on your thread. Whether it is oils from your hands or a coating on the thread, it can create a fisheye. So when people ask, can I just use some braided fishing line? Well, as you will see below, no you can not. One of my favorite fishing braid is Diawa 8x J-Braid. It appears to be smooth, consistent in color and plenty strong but it has zero stretch and a coating. Here is before finish.

The J-Braid does wrap pretty nice for something with no stretch but when it is time to add finish, it hates it. You can not bet a better example of fisheye than that!

All of these examples were doing on the same rod blank at the same time with Flex-Coat High Build Ultra-V rod finish. You can see above how the braided fishing line is trying to repel the finish and has created a bare spot along with wavy finish.

Thread and Finish Done Right

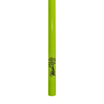

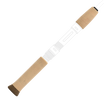

Just for the sake of comparison I have to show my favorite thread and color option. The ProWrap Nylon in 862 Black. Here it is wrapped, no color preserve used and before rod finish is applied. It is smooth, has just the right amount of stretch and packs nicely.

Here it is with one coat of the Flex-Coat High Build Ultra-V rod finish. The nylon 862 gives the deepest and richest blank once finish is applied.

Although that could've probably use a little bit more finish or a thin second coat, there it is with one coat, no color preserver and no heat used. Each thread option was just fully coated with thread finish and left to its own devices.

Hopefully this will shed a little light on the why and why nots when it comes to choosing thread for your next rod build or even for a quick repair.