Ever wonder what goes into making your fishing rod blank? Let’s dissect the materials and process it takes to create a rod blank that is ready to be built into your next custom fishing rod. With the help of our friends at Lamiglas in Woodland Washington, we will get a sneak peak inside this unique process.

Since 1951, Lamiglas has built a legacy as one of America’s original rod manufacturers, pioneering fiberglass, graphite, and composite designs that set the standard for performance. For generations, anglers have trusted Lamiglas rods for their craftsmanship, innovation, and proven success on the water.

Mud Hole and Lamiglas have a long standing relationship so when we had the idea to walk you through a step by step process of how a rod blank is made, it was an easy choice. I got to sit down with Lamiglas President John Posey while at ICAST to chat about all things rod building. He walkaed me through some of the cool things that go on at Lamiglas as well as promised an inside look at their manufacturing so we could pass along the knowledge of blank construction.

The Materials

To begin the rod blank process, a material must be selected. Most rod blanks are made from graphite, fiberglass, or a composite blend of the two. Although I do not have any hard data graphite tends to lead the way for its sensitivity and lightweight properties, while fiberglass provides durability and a unique action that is hard to replicate. Composite blends allow builders to combine the best characteristics of both. The choice of material directly influences the rod’s intended application, whether it’s for delicate trout fishing or heavy offshore angling. Each manufacture has unique blends and proprietary materials that makes their rod blanks exclusive to their business. No matter the material selected it must be in a sheet form to create a rod blank.

Rod Blank Prepreg

The raw graphite or fiberglass material is typically pre-impregnated with resin, known as “prepreg.” This refers to carbon fiber fabric or sheets that have been pre-impregnated with resin, during the manufacturing process. Because the resin is already evenly distributed throughout the fibers, builders don’t need to manually add it during rod-making or other composite applications. This offers several key advantages: the resin-to-fiber ratio is precisely controlled for consistency, ensuring uniform strength and weight; the material is easy to work with since it’s ready to be rolled, molded, or layered without messy resin application; and the finished product delivers higher performance, resulting in stronger, lighter, and more reliable fishing rod blanks.

A unique fact about prepreg is that these rolls are stored in carefully controlled environments to maintain their consistency and prevent premature curing. This step is crucial because the resin-to-fiber ratio determines much of the blank’s strength, weight, and sensitivity. They are often refrigerated for short term storage and can be frozen for long term storage.

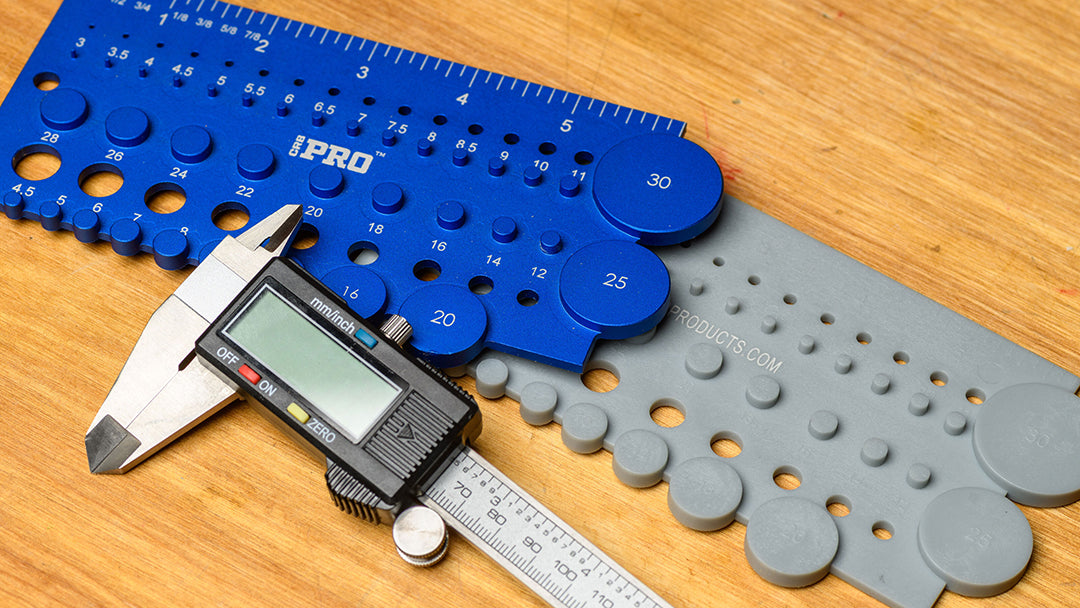

Cutting the Patterns

Next, technicians cut the prepreg sheets into precise patterns. These patterns are shaped to correspond with the taper of the desired blank. Each cut is angled and measured to ensure the blank will achieve the correct action—fast, moderate, or slow—and the right level of power. These pieces of material that are cut are called "flags".

Cutting is done with incredible accuracy, as even small variations can change the final performance characteristics of the rod. For years, these flags were cut by hand, but today CNC machines have transformed the process by delivering superior precision, reducing waste with intelligent nesting software, and using interchangeable tools such as oscillating or drag knives to prevent fraying and produce clean, smooth edges.

Tacking the Material to The Mandrel

The blank roller has specific blueprints and the collection of flags to create each individual rod blank. Although a complete blank series will have the exact same material, it is the pattern that creates the length, power and action of each blank. To attach the material to the mandrel a hot iron is used to tack the edge of the material to the mandrel before it is rolled.

Blank Rolling

The cut prepreg patterns are then rolled around a tapered steel rod called a mandrel. The mandrel serves as the mold that defines the inside diameter and taper of the blank. Technicians carefully align the prepreg layers as they roll them onto the mandrel, making sure the fibers run in the intended directions.

Some layers may be placed at different angles (for example, 0°, 45°, or 90°) to reinforce the blank in specific ways. This layering process is what gives the blank its unique balance of strength, flexibility, and responsiveness.

The blank rolling machine consists of two heated plated that slide is opposite direction beneath each other to roll the material around the mandrel. These plates not only slide in opposite directions but they can also pivot that accounts for the taper along the mandrel to assure even pressure and a perfect roll every time.

Blank Wrapping

Once rolled, the blank is tightly wrapped with cellophane or a special shrink tape. This step compresses the layers of prepreg onto the mandrel, squeezing out any trapped air and ensuring a uniform structure. The tight wrap also helps the resin flow evenly during curing, preventing weak spots or voids in the blank wall. The precision of this wrapping process plays a huge role in the overall consistency of the finished blank.

Blank Curing

The wrapped mandrels are placed into large curing ovens, where they are heated for several hours at controlled temperatures. The ovens at Lamiglas are tall enough to cure a 14 foot one-piece rod blank!

The blank are suspended in racks to hold them secure and straight while inside the oven. During curing, the resin in the prepreg melts, flows, and then hardens, locking the fibers together into a solid structure. This is the transformation point where the flexible prepreg layers become a rigid fishing rod blank. Manufacturers carefully monitor temperature and timing, as any inconsistency can affect the blank’s strength and action.

Cellophane Removal

After curing, the blanks are allowed to cool before the outer tape or cellophane is removed. This reveals the rough surface of the cured blank. The blank, while still on the mandrel, is placed in a machine that attaches the tag end of the cellophane to a wheel that pulls the tape off of the blank.

Removing the tape is a delicate process, as technicians must ensure the blank is not damaged during this stage. At this point, the blank has taken its final shape, but it still requires finishing steps before it’s ready to be built into a rod.

Mandrel Extraction

The steel mandrel, which has been inside the blank throughout the curing process, is carefully extracted. Because the blank has hardened around it, the mandrel must be pulled with precision to avoid cracking or splitting the blank.

Manufacturers often use lubricants or release agents on the mandrels prior to rolling, making this process smoother. In addition to release agents each blank has a unique "puller" that slide onto and matches the diameter of the mandrel that acts as a key to unlock the blank from the mandrel. Once the mandrel is removed, the blank is hollow and ready for further refinement.

Sanding the Blank

The cured blank typically has a rough, uneven surface, so it undergoes sanding to create a smooth, uniform finish. Sanding also helps reduce weight and bring the blank to its precise diameter specifications.

Some manufacturers leave their blanks unsanded, giving them a raw finish that many anglers find appealing. There is really no right or wrong when it comes to sanded or unsanded but it certainly does give the rod blank a different aesthetic.

Painting or Coating

Finally, the blank is given its outer finish. This may include painting, clear-coating, or applying a protective gloss. The finish not only enhances the blank’s appearance but also adds a layer of protection against UV rays, scratches, and moisture. Manufactures choose to paint or coat their blanks in a number of ways. The most common are or spraying, squeegee or dip coat. Lamiglas uses either squeegee or dip coating. The squeegee method is when the blank is pulled through a round squeegee with a hole in the middle that gives it a nice even coating. The method you see below is the dip-coating. It is exactly what it sounds like, blank are dipped down into this tube that is filled with a particular coating and then hung to dry. That dip pipe at Lamiglas goes down 11 feet into the floor!

At this stage, the blank is also inspected for straightness, strength, and cosmetic quality. Any that do not meet strict quality standards are discarded or recycled. As the blank move into final inspection they are also hand polished. This give the blanks a nice clean shine while giving a hands-ons up close inspection.

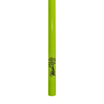

Bagging and Tagging

Last but not least the blanks are set to be bagged and tagged to head out to customers and dealers. Pictured is one of their famous centerpin blanks "The Closer". Mud Hole carries four different options in this blank. The Closer features a responsive tip for precise float control and a strong backbone to handle powerful fish in current. Lamiglas has created a unique blank that bends very parabolically and reacts to bites quickly. You have to feel it to believe it.

The creation of a fishing rod blank is a highly technical process that combines precision engineering with hands-on craftsmanship. From selecting the raw materials to rolling, curing, sanding, and finishing, each step is carefully controlled to ensure the final product performs exactly as designed. The result is a blank that serves as the foundation for a custom fishing rod—strong, sensitive, and tuned to deliver the perfect action on the water.

A special thank you goes out to the team at Lamiglas for providing imagery into this unique process. Since 1951 they have been making some of the best blanks in the world and Mud Hole is proud to stock all of their incredible models.