When it comes to custom rod building, few choices spark more debate than whether or not to use metallic thread for guide wraps. Metallic thread has long been a staple in decorative rod work, offering eye-catching shine and premium aesthetics. However, like any material, it comes with advantages and limitations that every rod builder should understand before committing it to a build. So, should you use metallic thread on your next custom rod, or is standard nylon the better option? Let’s break it down.

Why I Like Metallic

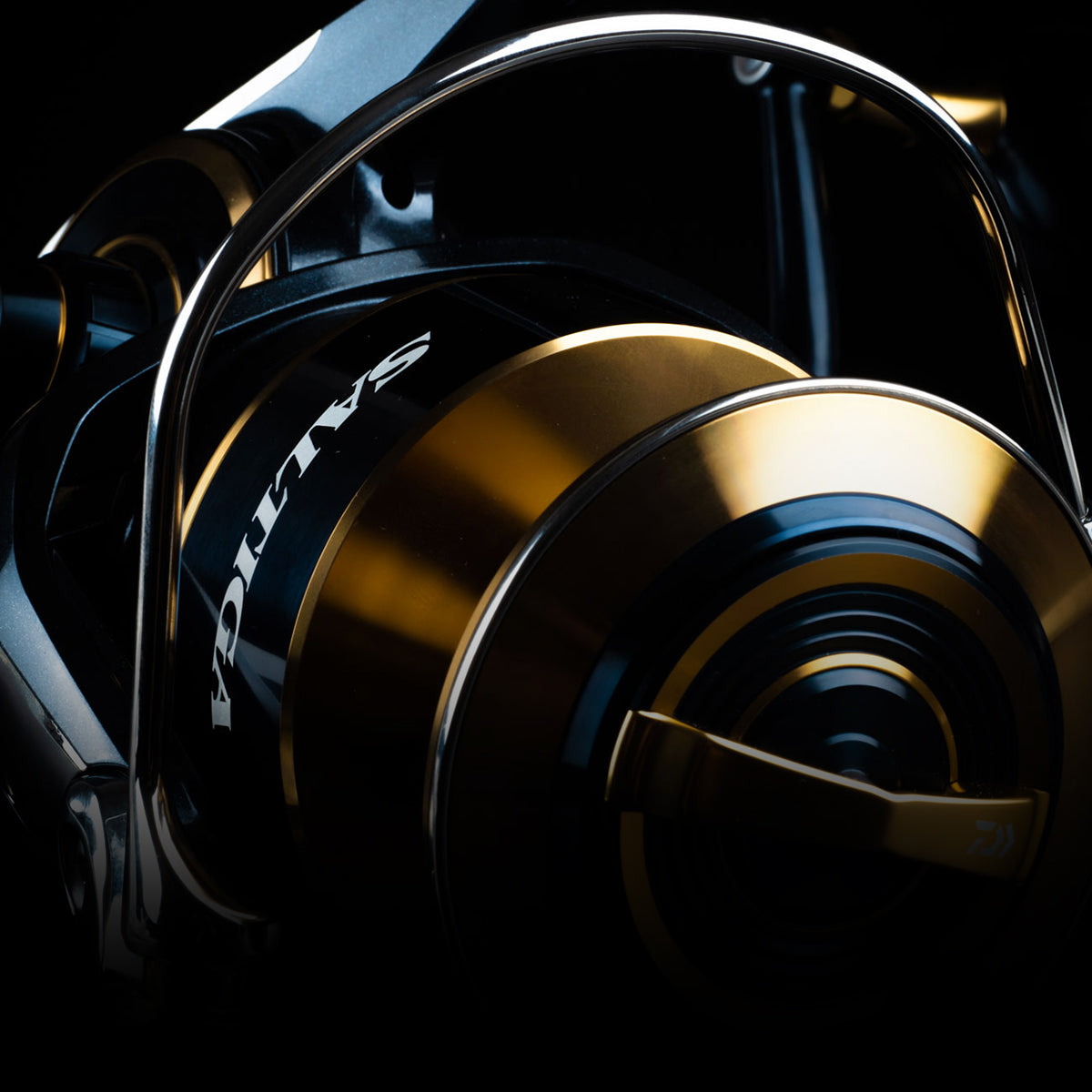

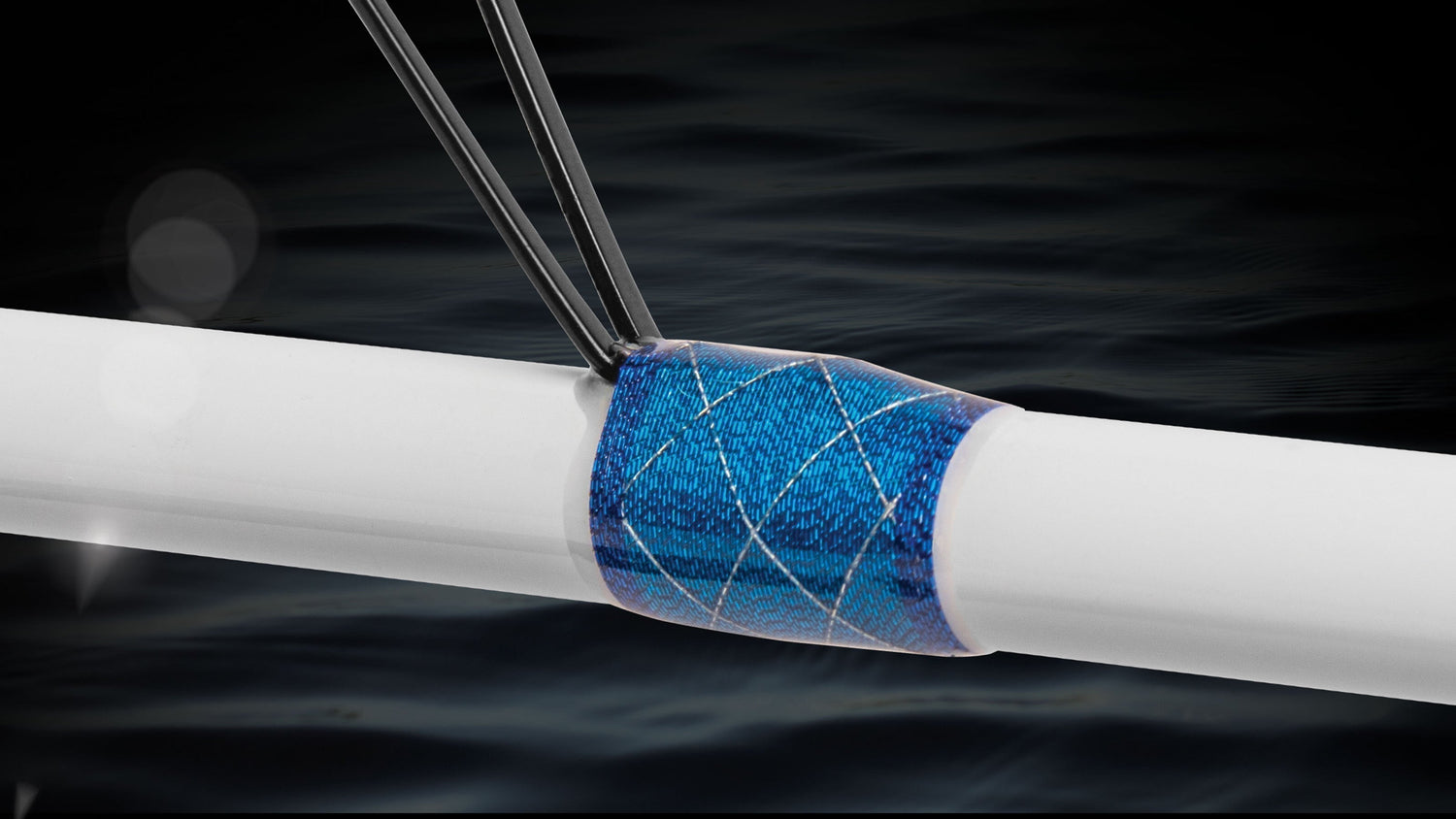

One of the biggest reasons builders choose metallic thread like ProWrap Metallic or ProWrap Electra is appearance. Metallic thread instantly elevates the visual impact of a rod, adding flash, depth, and contrast that standard thread simply cannot match. For showcase builds, presentation rods, or customs meant to stand out on the deck or in the rod rack, metallic accents around guide wraps can create a high-end, professional look. This is especially popular on saltwater rods, offshore builds, and commemorative or gift rods where aesthetics matter just as much as performance. As many of you know I’m not much of a guy for flash, it’s not that I can’t, I just build to fish. The most decorative you see from me is a dragonscale wrap.

Metallic thread also holds its color extremely well. Unlike nylon thread, which often darkens or becomes translucent when epoxy is applied, metallic thread maintains its brightness and reflective finish without the need for color preserver, a big plus! This consistency makes it easier to achieve predictable results, particularly for builders who want their wraps to look exactly the same before and after finish is applied.

The Metallic Myths

That said, metallic thread is not without its drawbacks. One of the most common challenges is durability during the wrapping process. Metallic thread is typically less forgiving than standard nylon. It can fray more easily, especially when packing threads tightly or making sharp adjustments. Beginners may find it more difficult to work with, as mistakes are harder to hide and rewrapping sections can damage the thread quickly.

There are some considerations that I have heard over the years, but I do not necessarily agree with them. I have heard about the lack of strength and function metallic thread provides but I’m not buying it. The rumor is, due to its lower tensile strength it might not be suitable or possess the longevity on rods designed for heavy drag pressures, high-stress applications, or frequent hard use that standard nylon or colorfast thread does. For this reason, many builders reserve metallic thread for accent work rather than primary guide wraps. I do not have a scientific data to back up my claims that this myth should be busted, but I have used size A and silk on rod that have seen pretty heavy use, without fail.

Another possible myth to avoid metallics is weight, especially on light or performance-driven rods. Not sure I buy this one either. Yes, metallic thread is slightly heavier than standard thread, and when combined with epoxy, it can create extra weight, but I still feel other factors would create more of a problem than thread weight. I do understand any extra weight should be deemed as unnecessary, but I also wrote a blog about the weight of a decorative wrap and even it was VERY minimal. Read the blog Can A Decorative Wrap Weigh You Down?

There is also the issue of finish compatibility. Metallic thread can sometimes highlight imperfections more than standard thread. Gaps, uneven packing, or inconsistent epoxy coverage are more visible due to the reflective nature of the material. This means metallic thread demands a higher level of precision and finish work to achieve clean, professional results.

So when should you use metallic thread? It is an excellent choice for decorative accents, trim wraps, name wraps, and rods built with visual impact in mind. It also works well on heavier rods where added weight and slight reductions in tensile strength are not concerns, if you subscribe to that belief. If you do want to go down that road of metallics as guide wraps, I would start with the ProWrap Electra Metallic. Featuring increased tensile strength, Electra is durable enough to be used as a primary wrapping thread, not just a decorative accent. Its holographic metallic finish captures and reflects light with striking brilliance, giving your rods a bold, high-energy look that stands out both on the water and on the rack.

When should you avoid it? If you are building a rod strictly for performance, sensitivity, or extreme load applications, standard nylon or color fast thread is often the better option for primary guide wraps. Again, I personally do not feel that metallic thread should be avoided for any reason except that it isn’t nearly as forgiving or easy to work with as nylon.

Ultimately, the decision comes down to the goal of the build. Metallic thread is a powerful design tool when used intentionally and correctly. Understanding its strengths and limitations allows you to incorporate it where it shines most, while relying on traditional thread where performance truly matters. Like most things in custom rod building, the best results come from matching materials to the job, not just the look.