Whether you are new to rod building or have been a part of the community for years, you probably have met or heard of Bob McKamey. He was introduced to rod building during his teen years and shortly after highschool his Custom Tackle Supply was becoming the go-to place for builders.

For years Bob was a fixture at gatherings and trade shows spanning the US, often having his son Hunter along for the ride. For over 30 years Bob owned Custom Tackle Supply. He speaks fondly about customers visiting the shop, staying late to be sure orders got done and showing folks the beauty of the Tennessee hills on the weekends.

He recounts how his rod building knowledge came from both those who were his elders in the craft as well as trial and error. Many of his ideas or tips are rooted in practical use on the water. Making the rod a better tool to catch fish or be more efficient for the angler rather than just simply a work of art. That’s not to stay Bob doesn’t build a stunning rod but I believe many fisherman really connect with his way of building. "Bob’s got stories for days and a passion for teaching. One minute, he's recounting his best day of Smallmouth fishing, and the next, he’s dropping knowledge on setting up a fly rod handle—without missing a beat. You’ve got to stay sharp, or you might just miss a gem!"

In 2009 Bob McKamey became a part of Mud Hole Tackle here in Central Florida. A vital member of the team Bob brought incredible knowledge to expand the blanks and components as well as teaching new builders.

Speaking of new rod builders, I was one of them. During the summer of 2013 I had the idea to start building my own rods. As many builders do, I always had something I wanted to change about the rod I was fishing. I either liked the guides but hated the handle or wanted a different reel seat, so I took a ride a couple hours south to Mud Hole.

One of the first people I met was Bob. We got to talking fishing and what I wanted out of rod building. He gave me the 10 cent tour, we looked at many different components, blanks and what I needed to build. In addition, I got a book, DVD and a quick tutorial from Bob and back home I went.

Bob and I stayed in touch for the times I needed advice, and I really enjoyed the process. Over the next year I became friends with his son Hunter, who was in college and working at American Tackle. We fished tournaments when he wasn’t traveling for school events and in the fall of 2014, Bob said, “You ever thought about working at Mud Hole, I’ll put in a good word for ya…” Well, 10 years and countless memories later, I still enjoy it.

OK enough of the history, now lets get to the tips and tricks!

Guide Spacing

One of the most asked questions by all rod builders pertains to guide spacing. Many guide kits come with suggested spacing but as we all know, that can just be a suggestion. We always discuss using static deflection to get the best possible spacing for your custom rod build.

Spinning Guide Train

Let's stay with guide spacing for our next tip. For years, rod builders believed using larger guides would decrease ring contact and lessen line friction and maximize distance.

Well, we are all past that now. Concept guide trains have replaced the cone of flight and since most of the guides weight is in its ceramic ring, we use the smallest size to get the job done. Light and efficient is the way to go!

A great example of this is shown here in one of our chats with Bob on Mud Hole's instagram. Side note, if you aren't following us on social media, you are missing out!

As Bob mentioned in the video, it is more of a braid system. This is great for the common braid to leader connection and suitable for freshwater, inshore and nearshore rod builds.

The popular choices for the high frame, rapid reduction guides are the American Tackle TiForged and Fuji KL-H. In addition, the AT TiForged kit are actually setup specifically to the size of the spinning reel you will be using. For example, if you are fishing light freshwater and using a 1500 size spinning reel, your guide kit has been created to match that size reel.

Guess who hand picked and designed those TiForged Spinning Guide Kits... Bob, so you know it is right.

Before we get too far from that video I would like to mention Bob has been known for his nicknames and catch phrases. The "YEAH BOY", is always a favorite and can typically be heard across a convention hall. We also get a good "AWW HAIL", which is in response to a good joke, so if you get that one, consider it a gold star. Finally, we get a "HAAAY NOW", this is for landing a big fish, running into an old friend or when handing him a cold drink.

For nicknames, many refer to him as Uncle Bob, and not to be confused with age, Ol' Bob. Under no circumstances is it Old Bob. Mr. Bob and Mr. McKamey also works.

Fly Rod Guides

This one tip from Bob was particularly intriguing because it just made too much sense. I admit, I am partial to fly fishing and Bob loves it dearly as well. During on of our early fly fishing discussions we spoke about reel seats, handles and guides but of all the knowledge he provided one suggestion really stood out. It was proper stripper guide placement.

Our discussion was about fishing clients and dealing with giving casting lessons on the water. We were in the parking lot casting and testing blanks and stopped me as I when to pickup to make another cast. "That rod doesn't fit you well", Bob said. I stopped mid-backcast and as the line came back piling at my feet I looked at him like, "Huh?"

He said you throw it great but that is one I built and you are quite a few inches taller than me so that stripper guide is too close. As soon as he said it, I knew.

As I reached out towards the stripper guide to being my initial backcast with a haul, I was actually hitting the stripping guide with my hand. What has always been muscle memory for me in casting was being impeded by the guide placement. For a right handed caster, reaching out to grab the fly line at the stripper guide helps create a built in "haul" in your first backcast. So, the proper placement is key. The stripper guide should just be out of your reach. You want to grab the line right behind the guide with out making an effort or straining to reach.

One last fly rod tip. If you are unsure about how many guides you need for your custom fly rod build, just use the length of the rod plus one. That is the proper number of guides. So, a 9 foot fly rod will use 10 guides. The tip top does not count as a guide.

Handle Length

Another hot topic in rod building is your handle length. My approach comes from Bob's advice overs the year of using your arm length and body motion to choose what length fits you best. With some builds you want to key in on how you set the hook. A flippin' stick is one that if too short you miss out on some leverage and where it lays on your body will dictate how efficient your hookset can be.

Have a listen here as Bob discusses building a surf rod and how handle length translates into casting.

Each technique can be different but in surf casting, your distance can be your biggest asset.

Casting Guide Size

Ask five rod builders a question and you are likely to get five different answers. As I have said before there are not many wrong answers in rod building but we are always striving towards to best. Anytime you can throw it a little farther, be a little more accurate or reduce fatigue while fishing, I consider those a win.

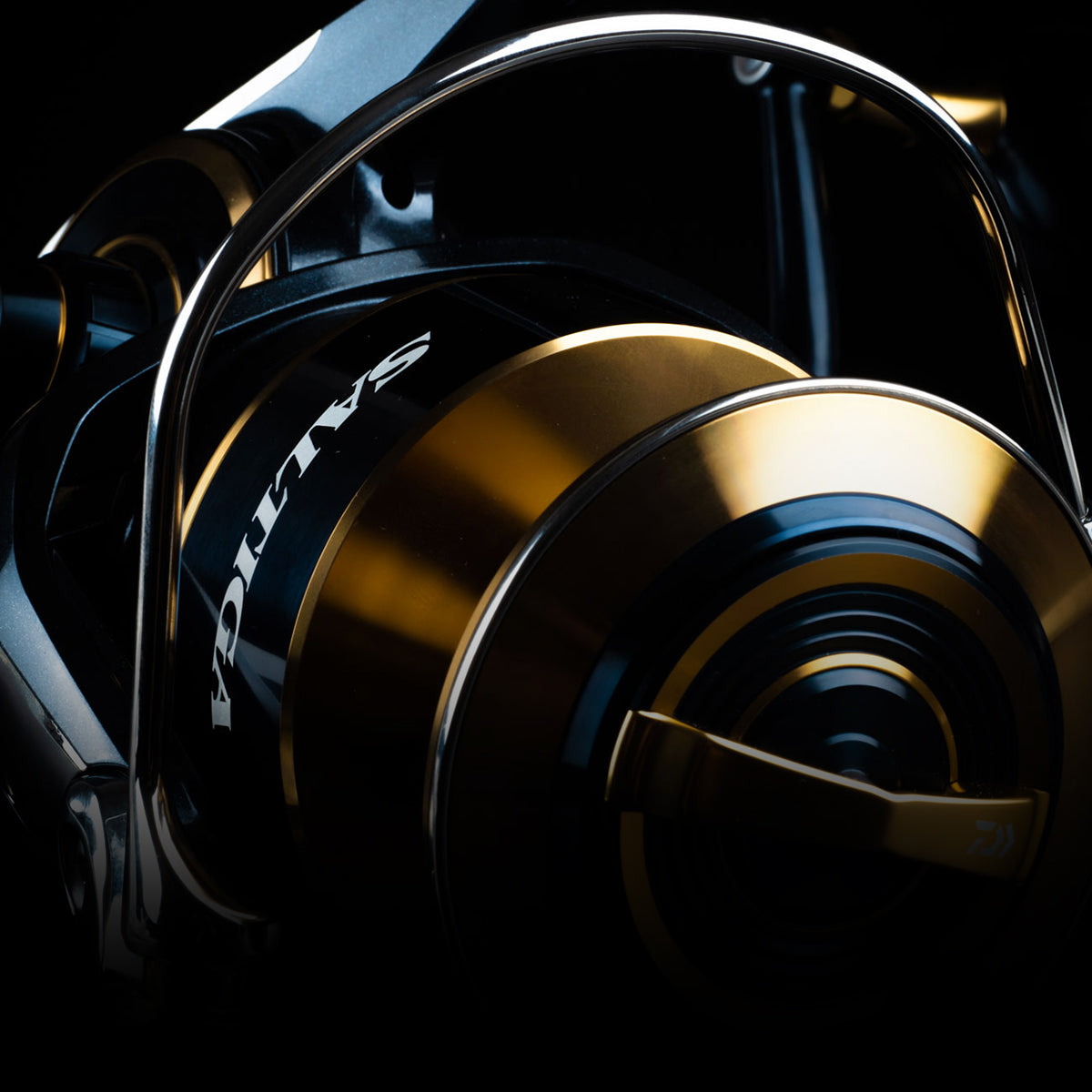

If you call in to Mud Hole customer service or watch Mud Hole Live, the size or type of reel is always discussed in relation to you guides. This tip might just be something you might not expect.

Perfecting Rod Finish

Last but certainly not least, I am going to leave you with a tip on rod finish. We all know a nice coat of rod finish can really make a good rod build great. There is a reason we spend so much time and effort to develop good tools and provide as much knowledge and assistance to help all rod builders with their rod finish.

In typical Bob fashion, this tip does not require any fancy tools or equipment. "I just use a plain ol' tooth pick", said Bob.

Every time I see him do it, I am amazing at how quickly he can dab his finish and then get it set in the rod dryer.