A reel seat arbor is a crucial but sometimes overlooked component in custom rod building. Its primary role is to fill the space between the fishing rod blank and the inside of the reel seat, creating a snug, centered, and secure fit. Without an arbor, the reel seat may wobble, shift, or even come loose over time, which can lead to discomfort, reduced sensitivity, and a weakened handle assembly. By providing a solid foundation, arbors ensure that the reel seat remains firmly in place, distributing stress evenly along the rod and maintaining long-term durability. They also help maintain precise reel alignment, which is essential for casting accuracy and comfort over long fishing sessions.

There are several types of arbors available to rod builders, each with its own advantages and best-use scenarios. One of the most traditional and widely used options is the tape arbor. For those that have watched any of the 125 episodes of Mud Hole Live, you know I can be quite outspoken about my preference to use tape arbors. Many of my comments are made in jest but in all seriousness, I’m a tape arbor guy.

Tape Arbors

When I say tape arbors, it means they are made from masking tape, these are created by wrapping evenly spaced bands of tape directly onto the blank until the reel seat fits snugly over them. The gaps between the tape bands are then filled with Pro Paste epoxy during assembly, creating a strong bond. Tape arbors are inexpensive, quick to install, and easy to customize for any blank diameter. However, they rely heavily on proper epoxy application for long-term stability and should be built with precision to avoid water intrusion or uneven alignment.

The glue-up process is very similar for each of the three arbor types and I wanted to mention, it is easy to get epoxy all over the reel seat, especially in places you do not want epoxy. I was taught and always suggest to use masking tape to protect the areas like hood covers or reel seat threads. Not only is it a huge pain to clean out epoxy from the threads, if you do no catch it and properly clean up the mess, you can ruin the rod build. We all have horror stories of epoxy gone wrong, so please protect your threads and keep an eye on your epoxy. Speaking of cleaning up epoxy, we use either 70% or 91% isopropyl alcohol you can purchase at any drug store.

Polyurethane Arbor

Another popular option is the polyurethane arbor. These are pre-formed, lightweight, foam-like cylinders designed to fit specific blank diameters and reel seat sizes. Because they are machined or molded to exact tolerances, polyurethane arbors provide a uniform, gap-free fit that often requires minimal modification.

They are extremely durable, resist water absorption, and offer excellent vibration transmission from the blank to the reel seat—making them a great choice for anglers who prioritize sensitivity. For installation reccommend gluing the arbor into the reel seat first. This gives you a secure bond between the seat and arbor before you begin reaming with your CRB Extreme Reamers. Once the Pro Paste epoxy is cured ream a little at a time, these arbors are VERY easy to ream and you do not want to take too much off too quickly.

Another reason to glue the arbor into the seat before reaming is you can have a much more secure grip on the reel seat during reaming rather than holding the arbor. What happens of you over ream your arbor or it is off center? Don't worry, all is not lost. Since they ream very easily, you could just using your reamers and completely take out all of the arbor and start over. If you over ream just slightly you can use a small tape arbor to fill the gap on one end of the arbor. Do not sweat it, Pro Paste will give you an incredible bond!

Another reason to glue the arbor into the seat before reaming is you can have a much more secure grip on the reel seat during reaming rather than holding the arbor. What happens of you over ream your arbor or it is off center? Don't worry, all is not lost. Since they ream very easily, you could just using your reamers and completely take out all of the arbor and start over. If you over ream just slightly you can use a small tape arbor to fill the gap on one end of the arbor. Do not sweat it, Pro Paste will give you an incredible bond!

Fiberglass Mesh Tape Arbor

A third option is the fiberglas mesh tape arbor, which blends some of the customization of tape arbors with the structural benefits of modern materials. Often to referred to as drywall tape, it is made from fiberglass mesh, is wrapped around the blank to build up diameter just like masking tape, but the open mesh allows epoxy to fully penetrate and bond directly to both the blank and the reel seat. This creates a lightweight but incredibly strong connection with excellent epoxy adhesion.

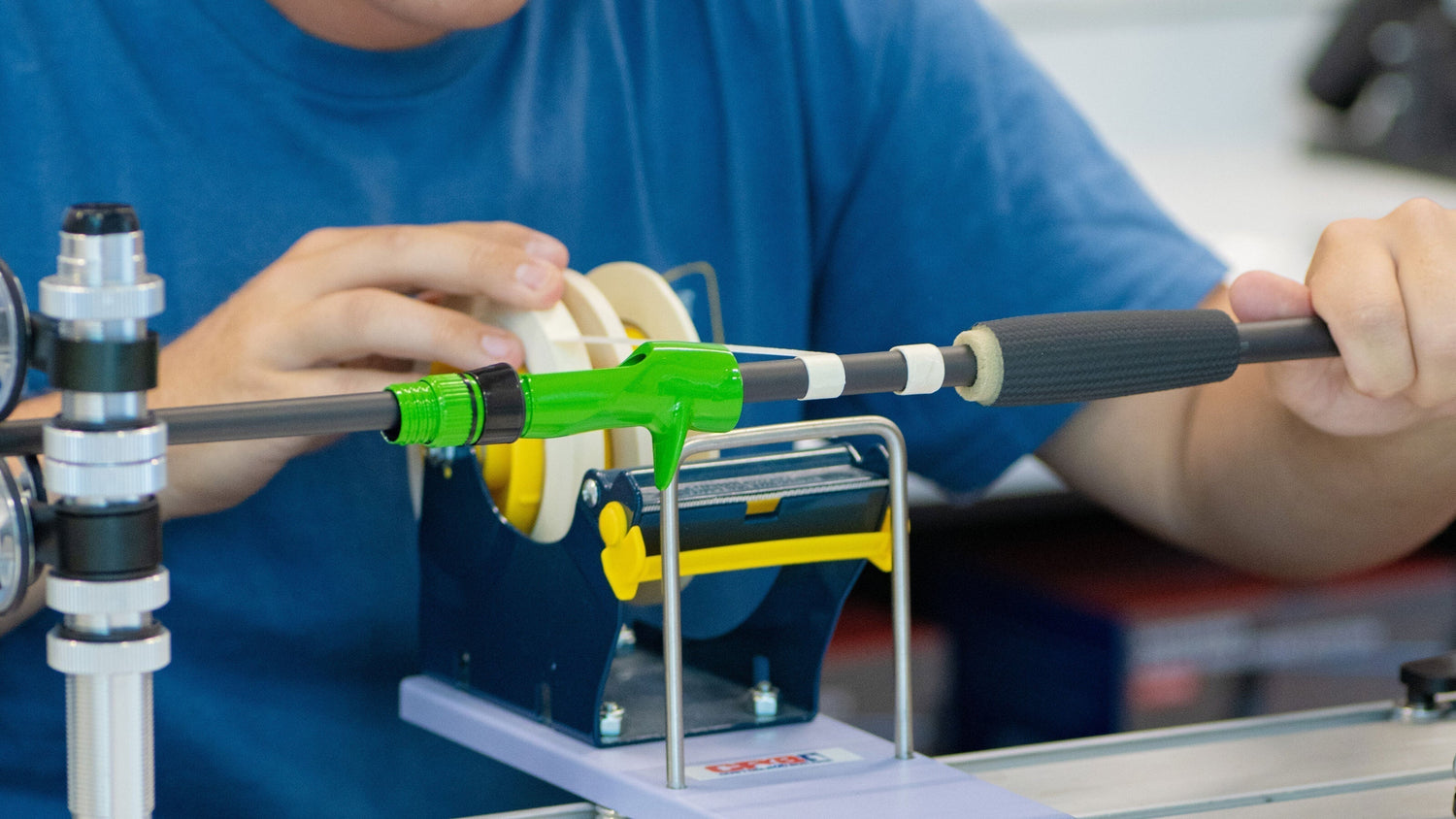

Fiberglass mesh tape arbors are also resistant to water damage and compression over time, making them more durable than traditional masking tape. They are particularly useful for heavy-duty saltwater rods or applications where maximum strength and moisture resistance are important. For the mesh tape arbor to work as designed, you must adhere to proper application of tape and epoxy. You you simply wrap the tape and then apply epoxy over the top, it will not penetrate through the mesh as the gaps in the mesh will not always be perfectly lined up. To demonstrate how it is done properly, professional rod builder and owner of The Decorative Studio Mary Christy.

As you can see, dry fitting is an important part of the tape arbors and then Mary backs off the tape and adds epoxy as she rewraps the mesh tape. This creates a bond without any gaps or voids in the epoxy and gives you the maximum strength for heavy duty rod builds.

Ultimately, choosing the right reel seat arbor comes down to balancing convenience, and performance needs as well as what you have confidence in using. Tape arbors are quick and effective, polyurethane arbors are precise and highly durable, and drywall tape arbors offer exceptional strength and bonding. No matter which type you choose, a properly installed arbor is essential for ensuring your reel seat is solid, secure, and ready to withstand the demands of countless fishing trips. In rod building, it’s a small step that makes a big difference in the overall quality and longevity of the finished product.